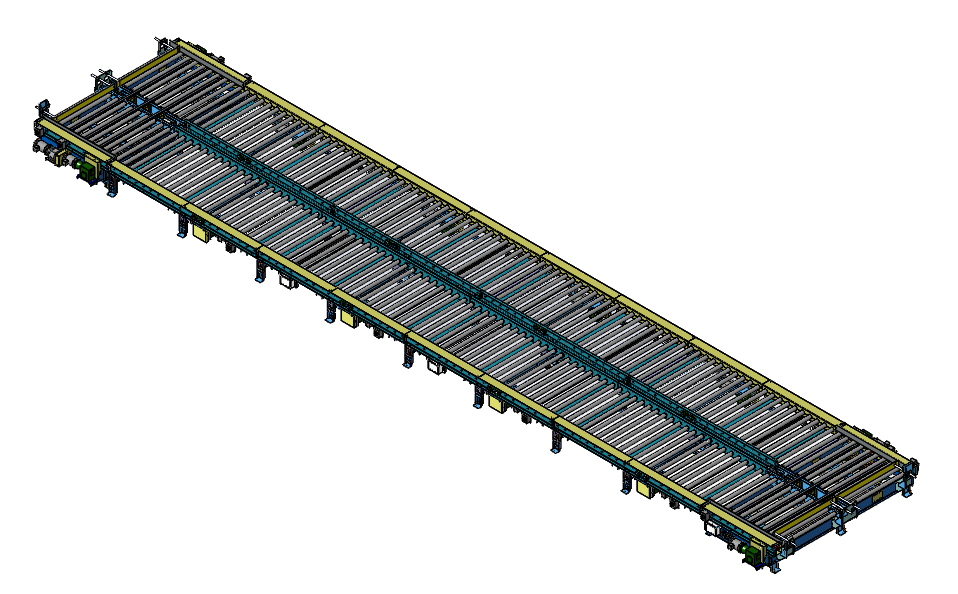

LEWCO’s Extensive Product Line – Available in Stainless Steel

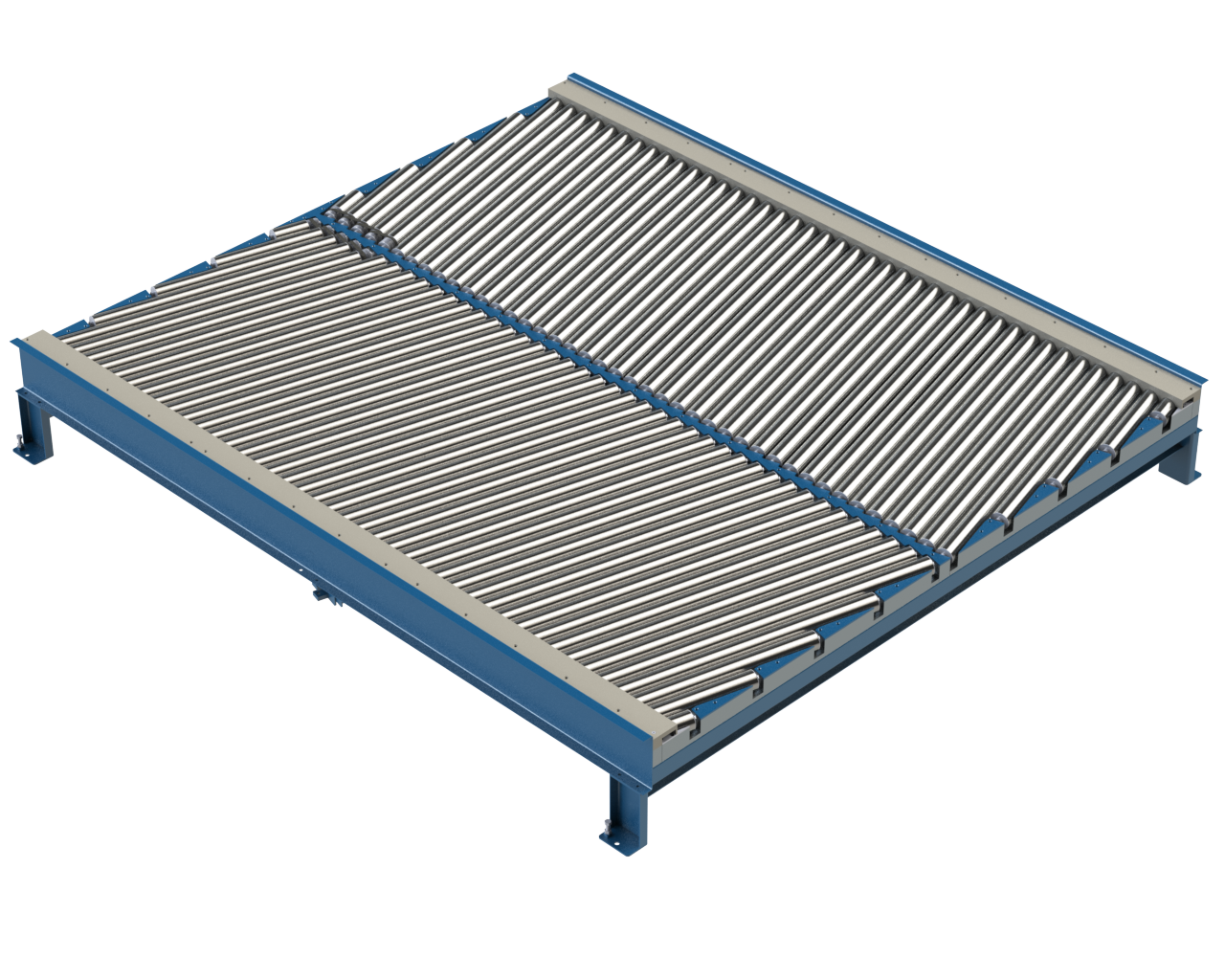

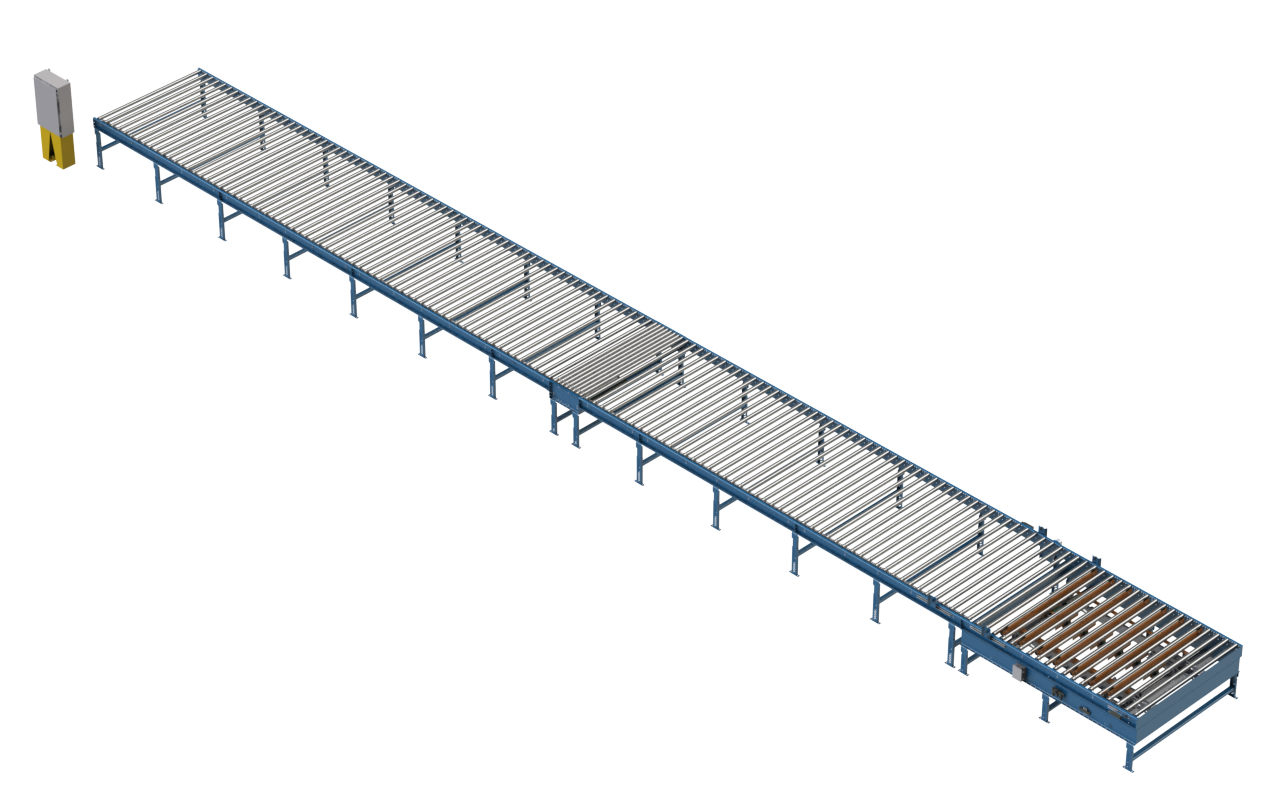

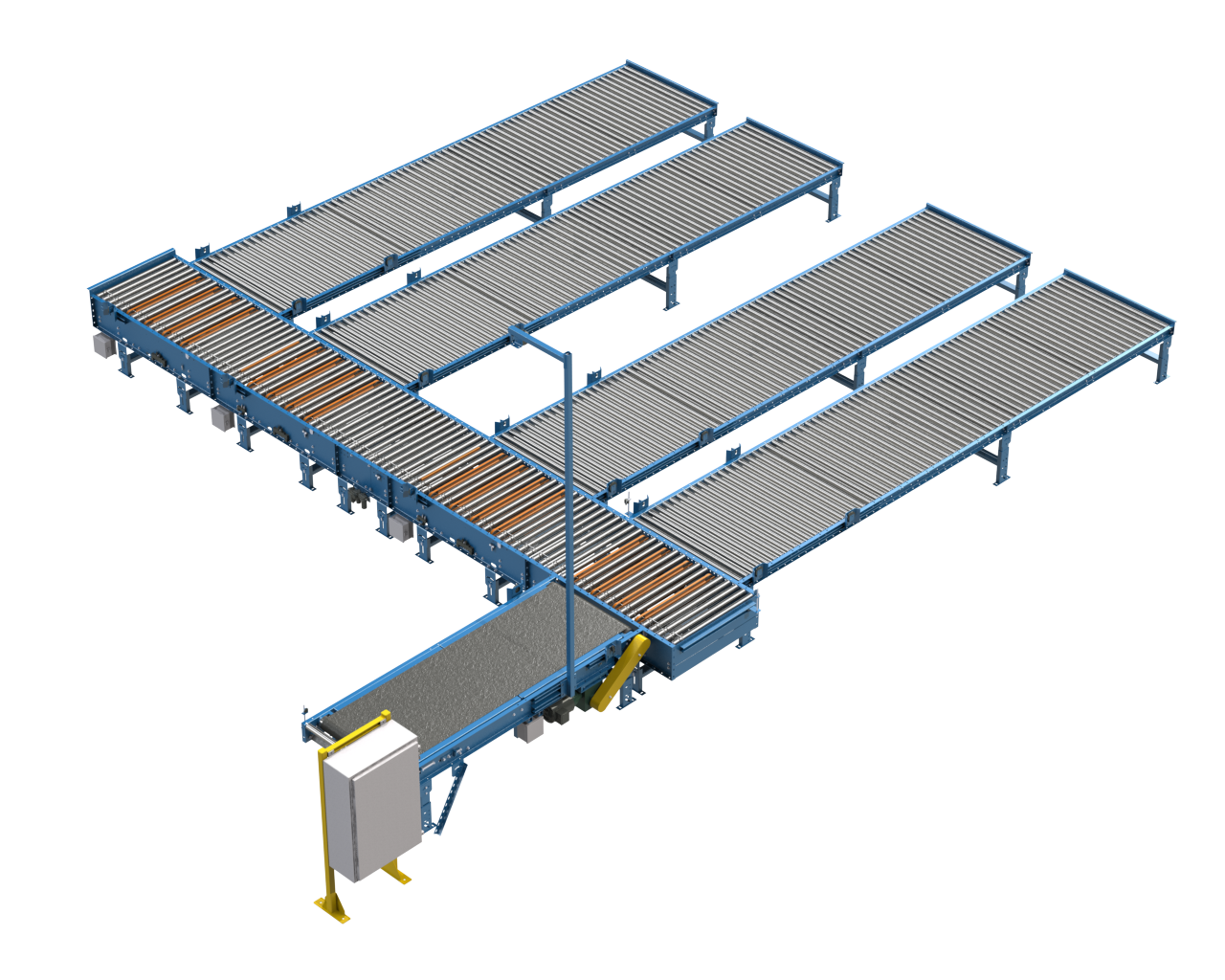

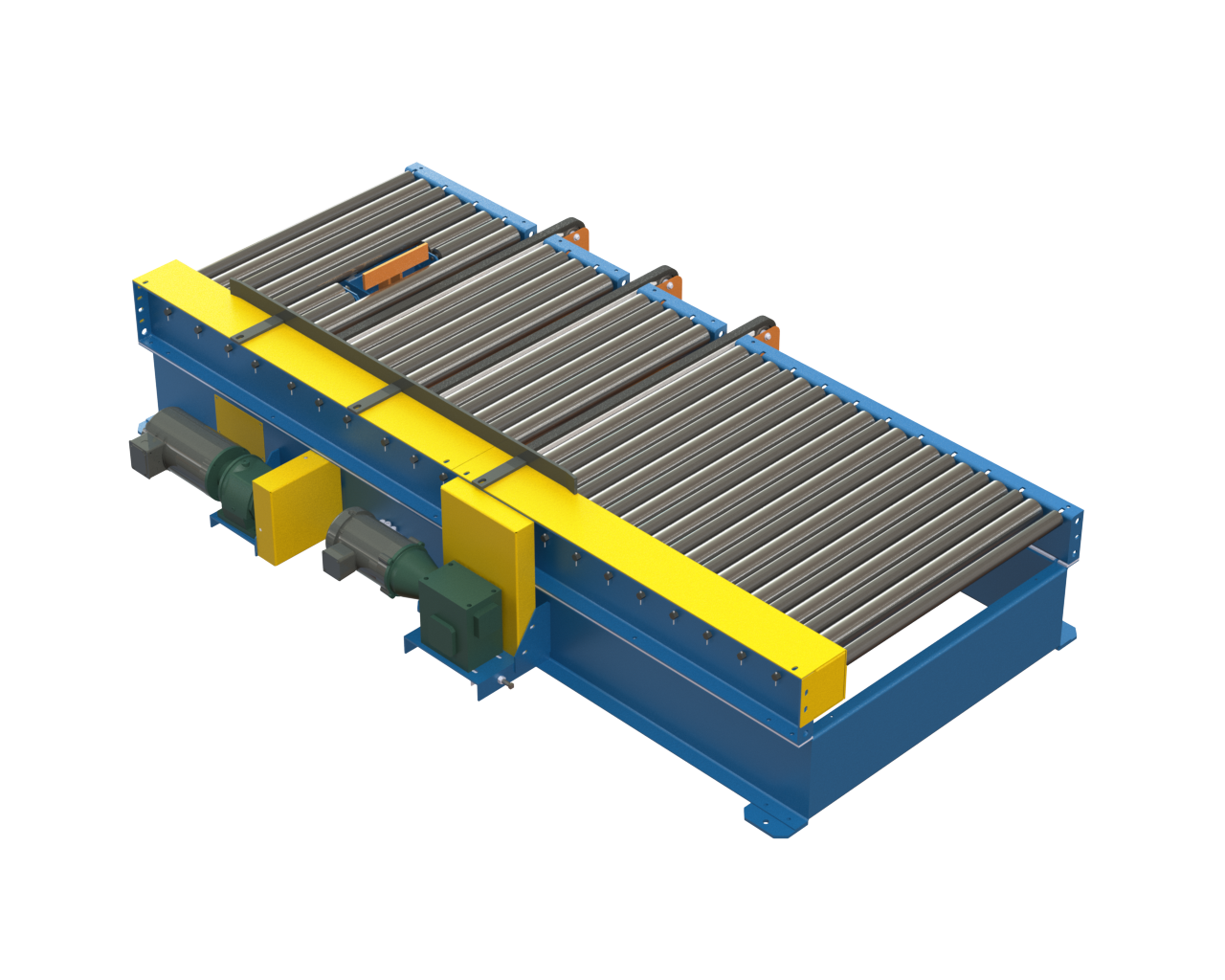

LEWCO’s extensive product line is available in Stainless Steel. LEWCO’s Stainless Steel Conveyors are perfect for wash-down applications. Our Stainless Steel Conveyors are generally manufactured with 304 grade Stainless Steel materials with the choice of mill finish or polished finish. Powered conveyor components include: wash-down motors, gearboxes, and bearings; stainless steel frame, rollers, and much …

Read More “LEWCO’s Extensive Product Line – Available in Stainless Steel”