Automated Solution Delivers Efficiency in Rice Bag Sorting

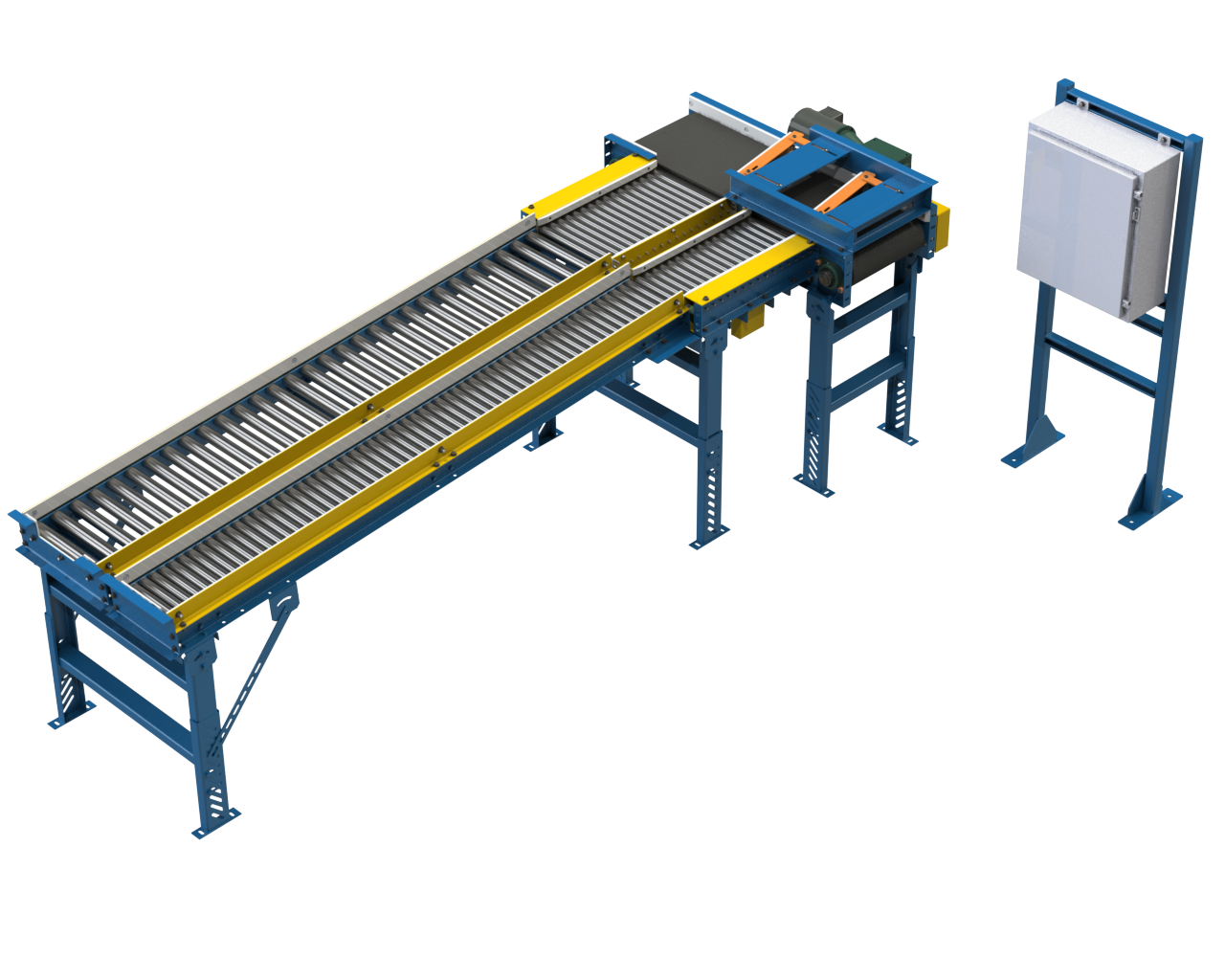

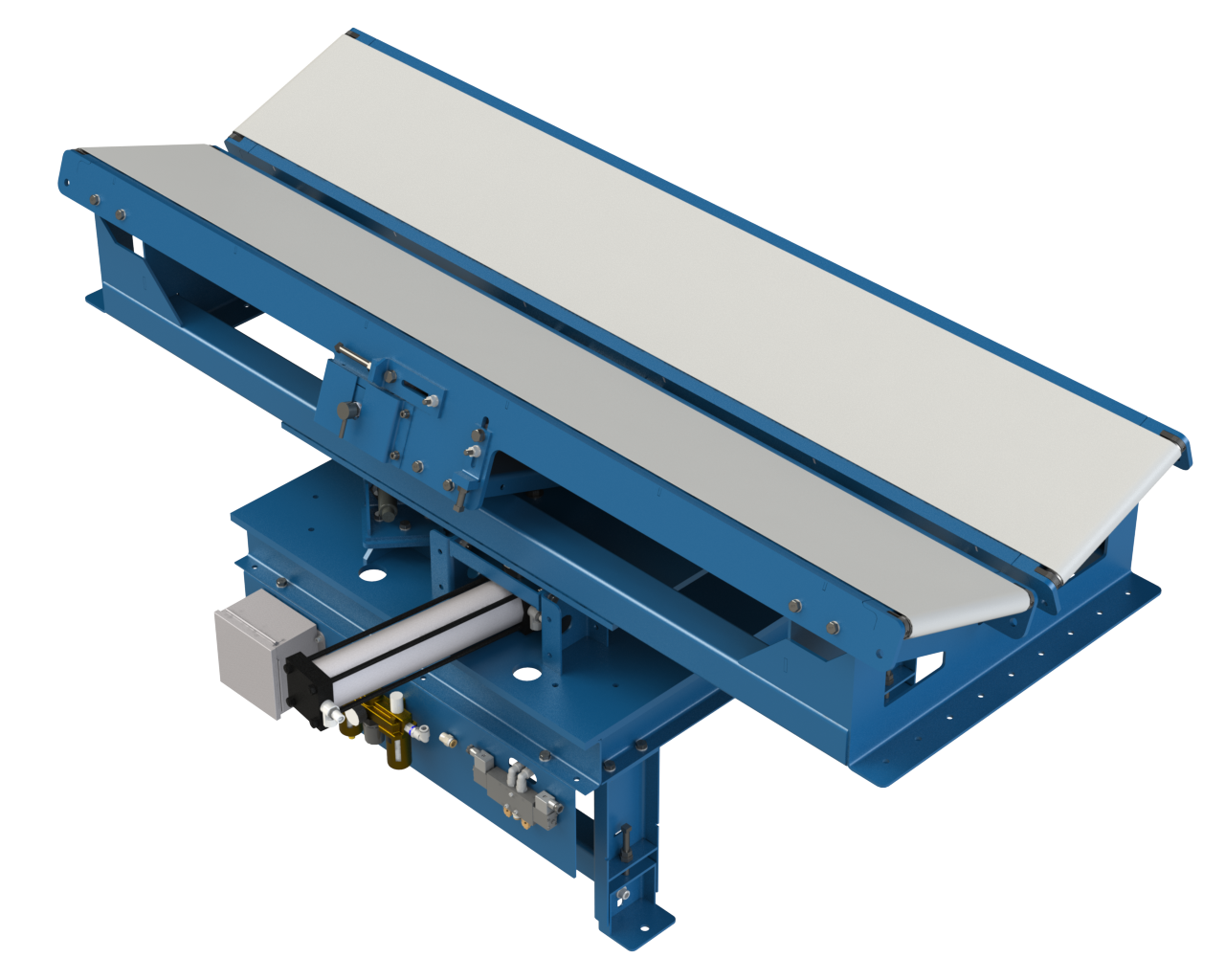

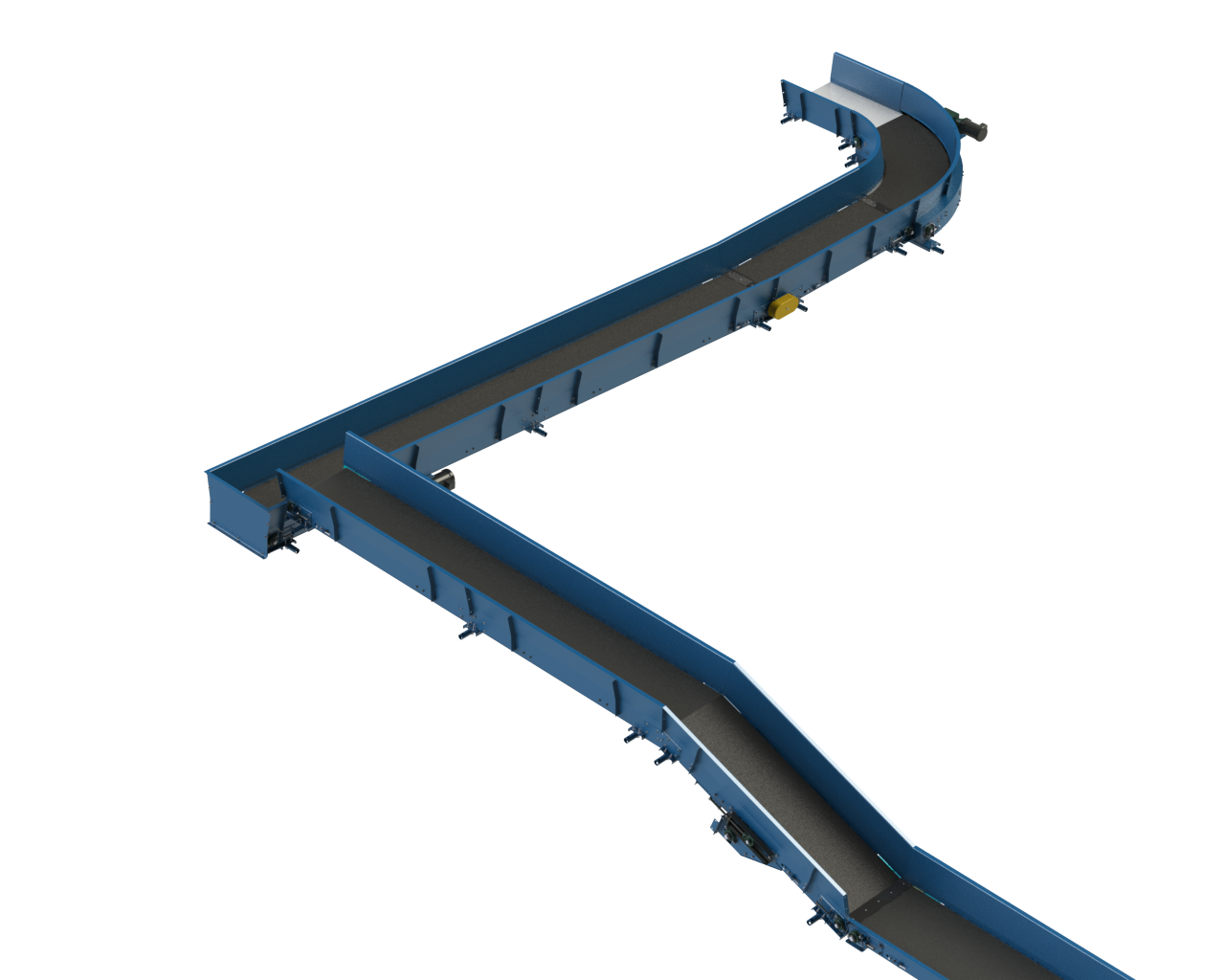

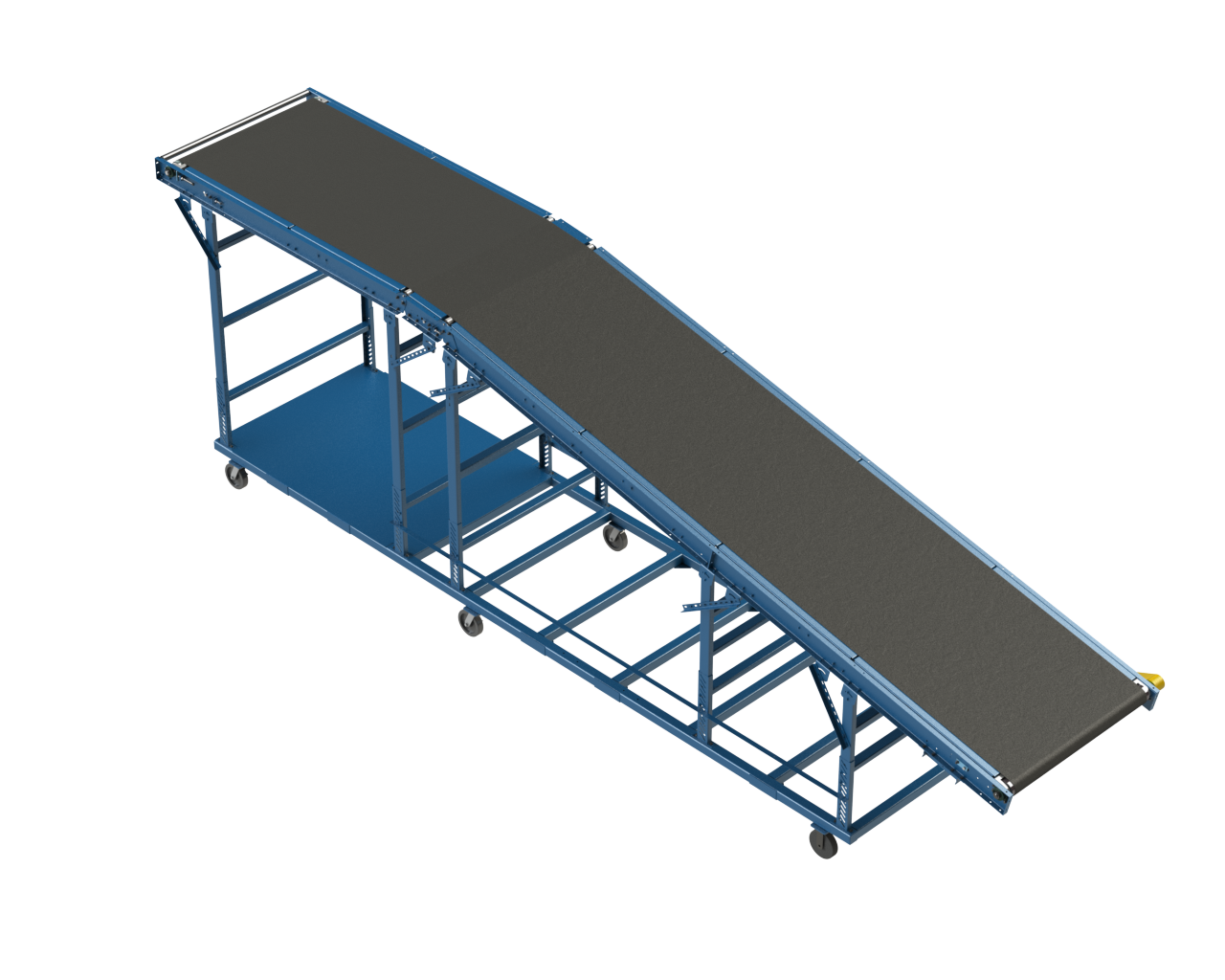

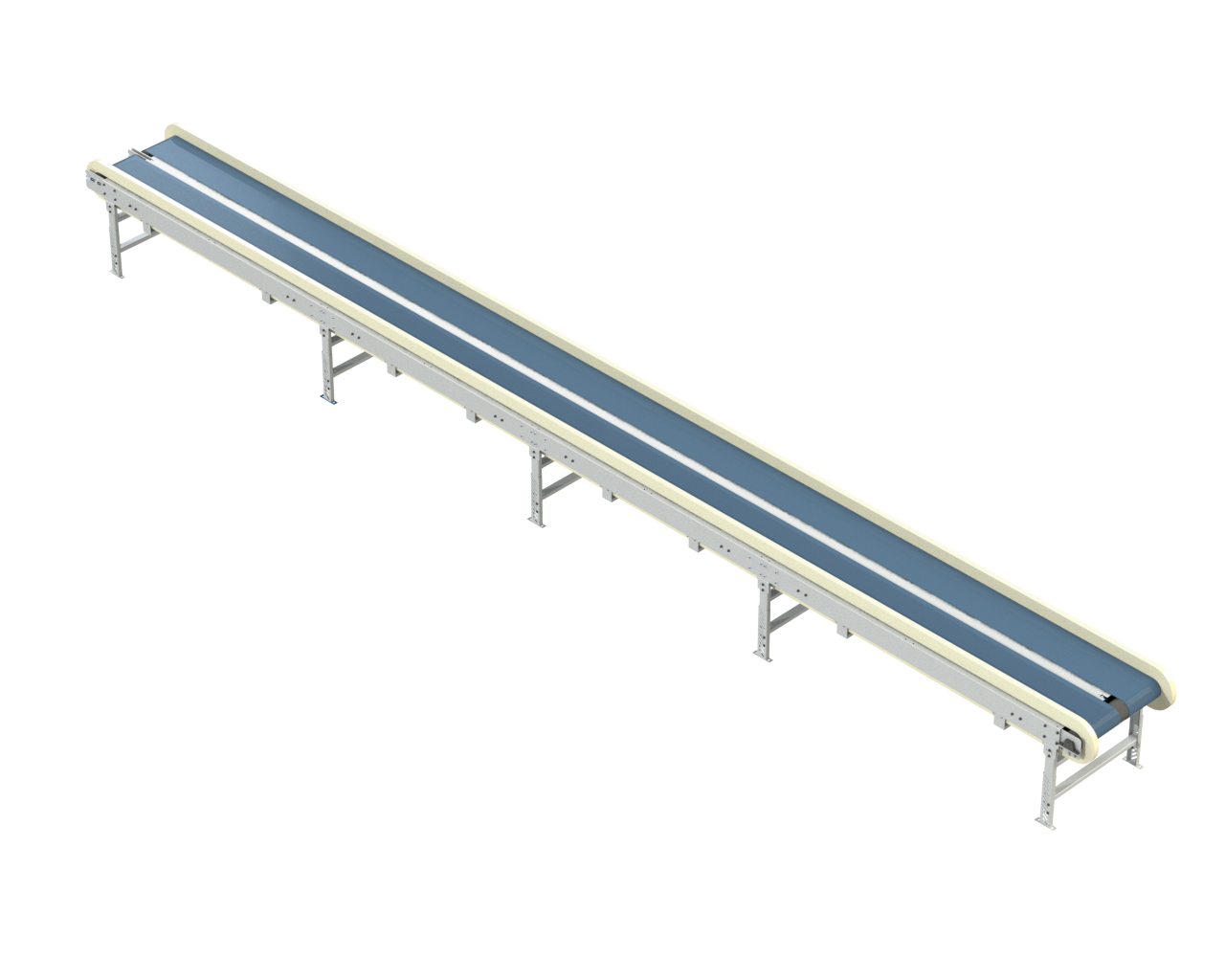

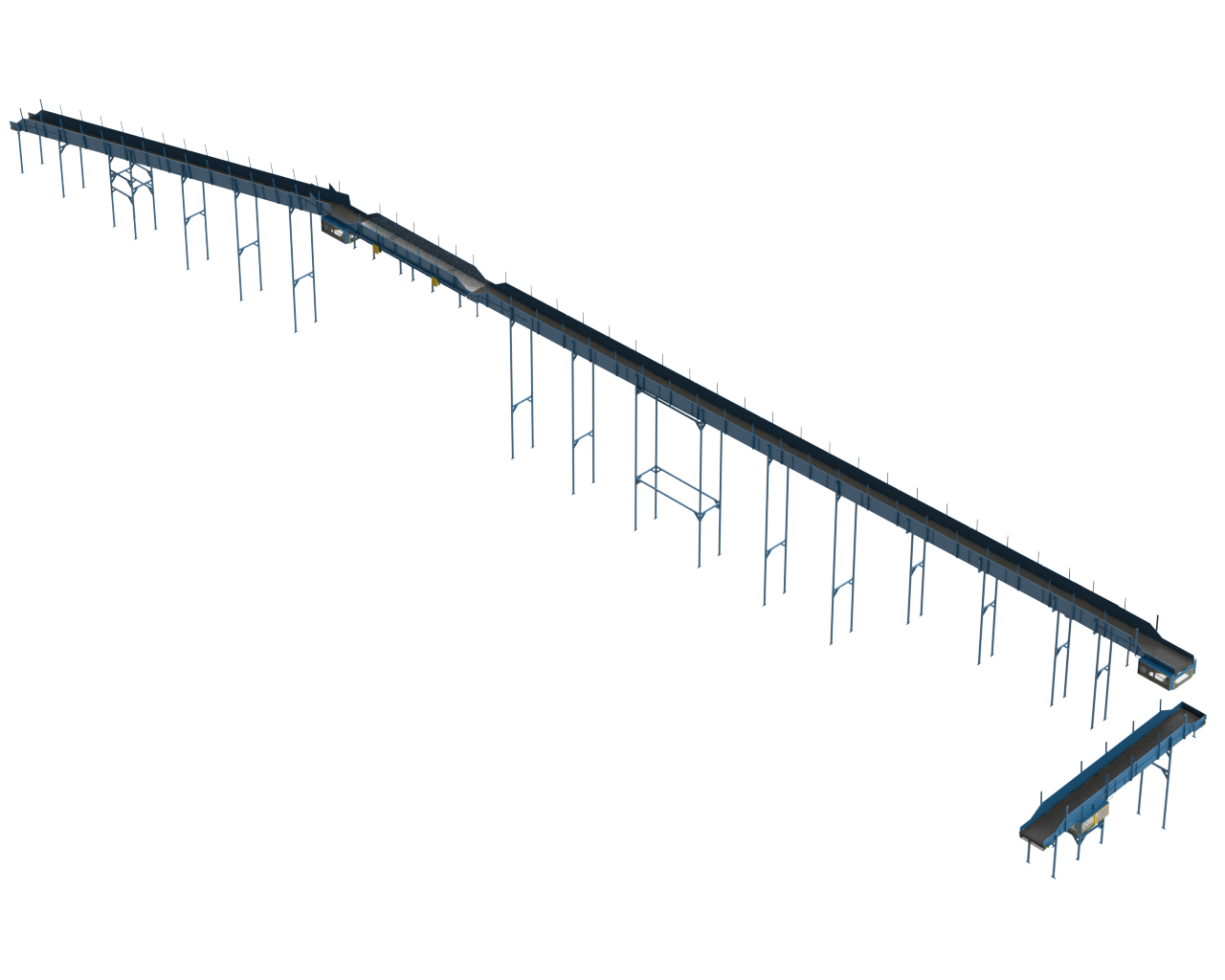

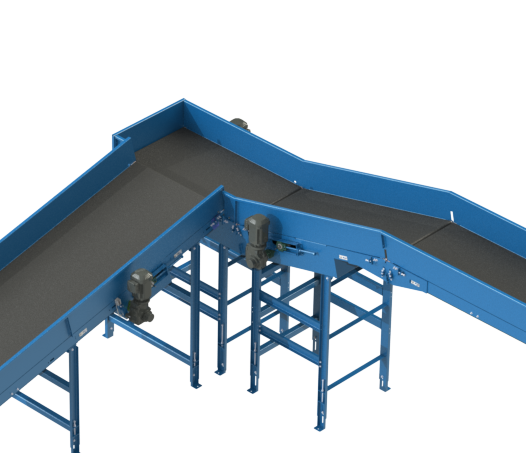

Our customer faced a pressing need for an automated solution to efficiently sort and transport their bagged product from the filling machine to the conveyors at their delivery dock. They had to handle hefty 100-pound bags of rice at a rate of 16 bags per minute. Recognizing the challenge, the customer turned to LEWCO, Inc. …

Read More “Automated Solution Delivers Efficiency in Rice Bag Sorting”