CDLR Conveyor System for 4K LB. Pallets

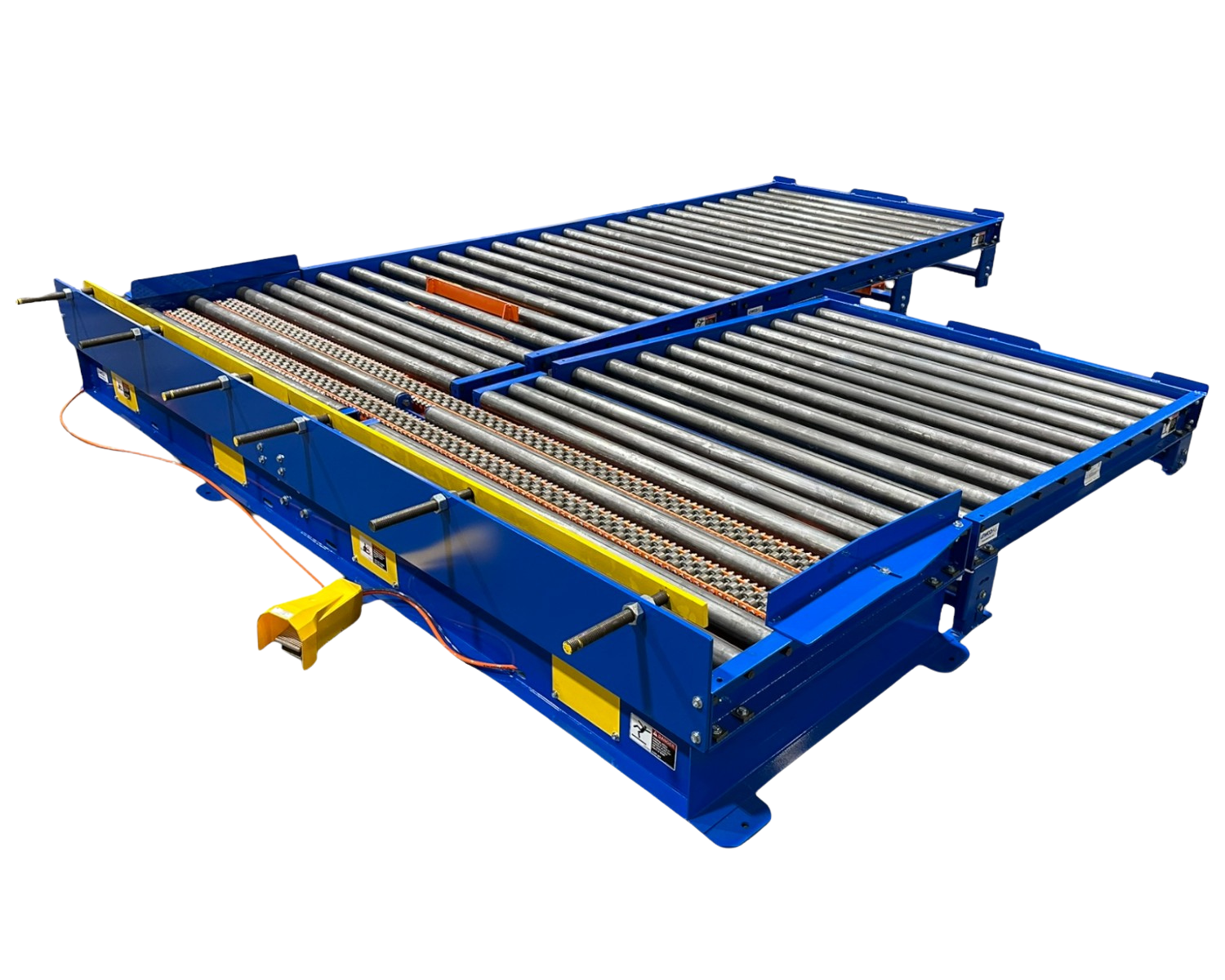

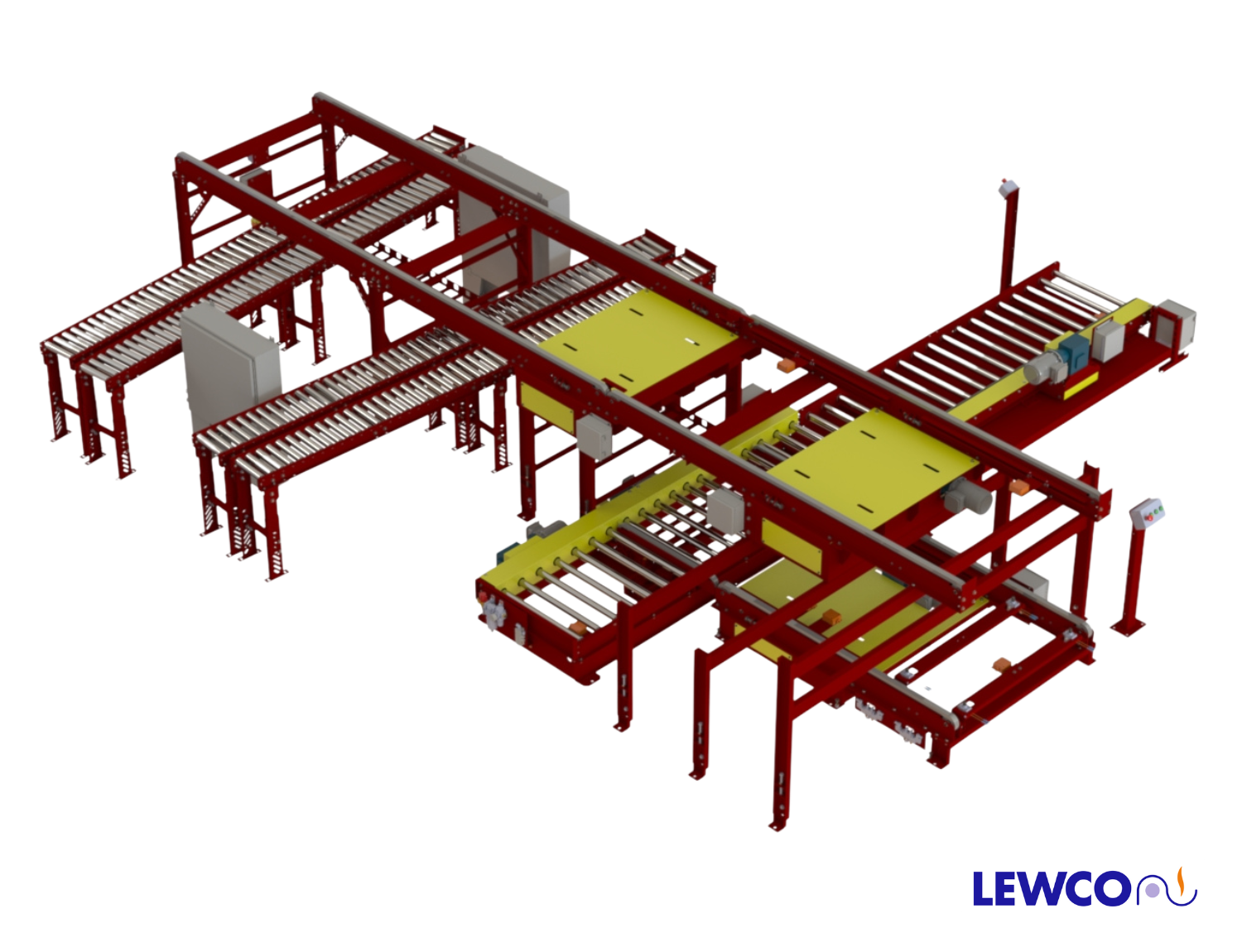

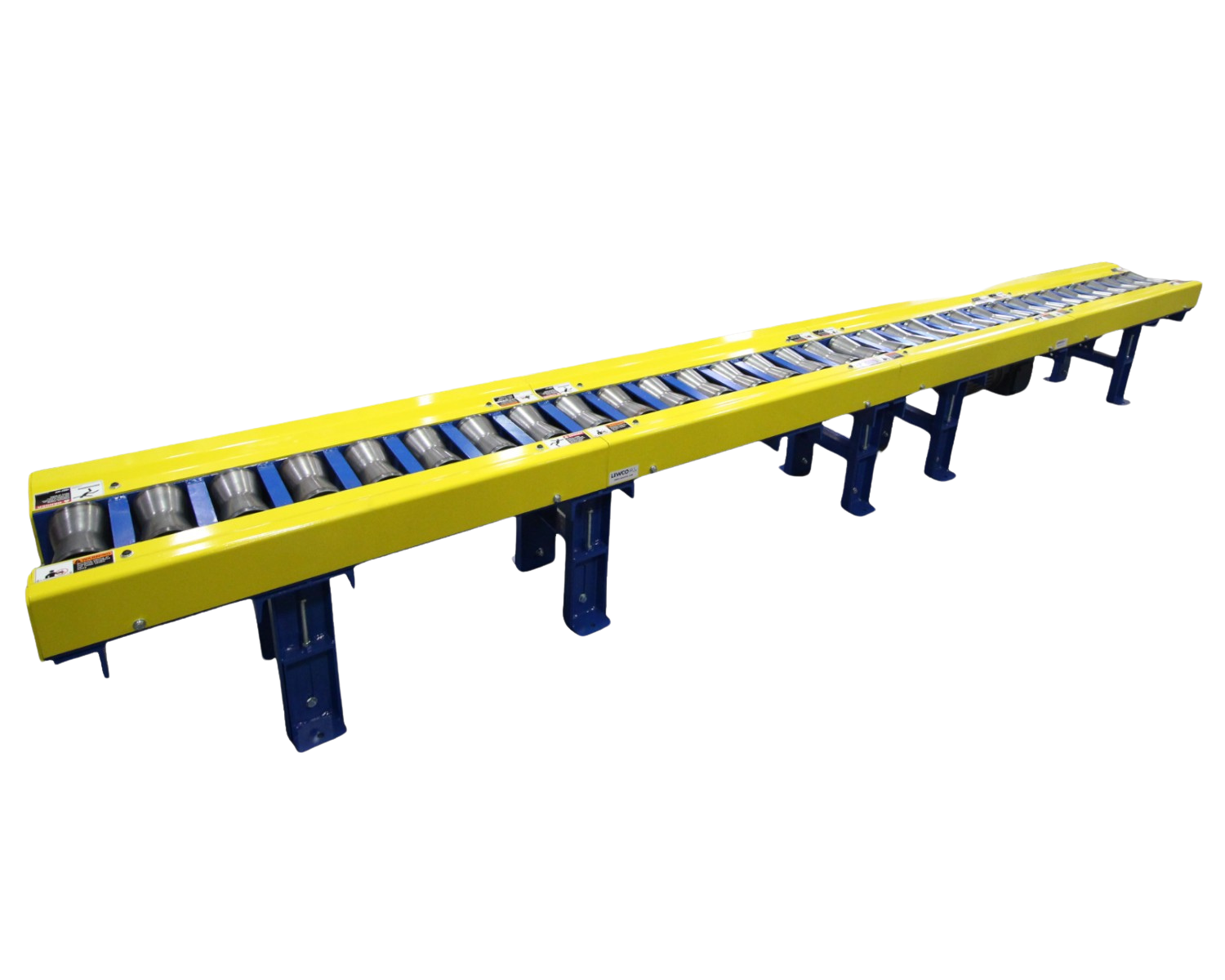

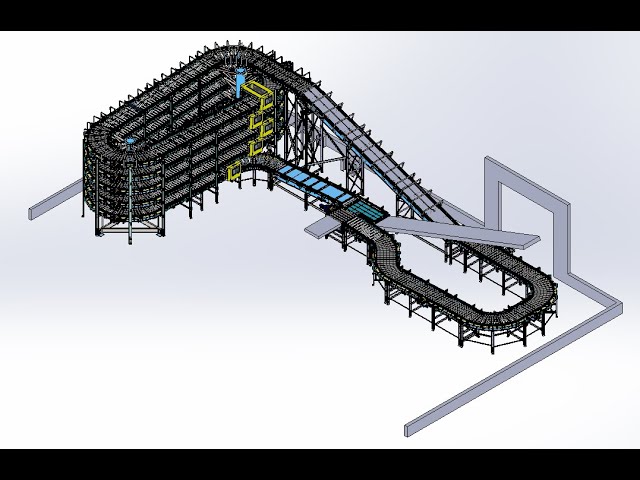

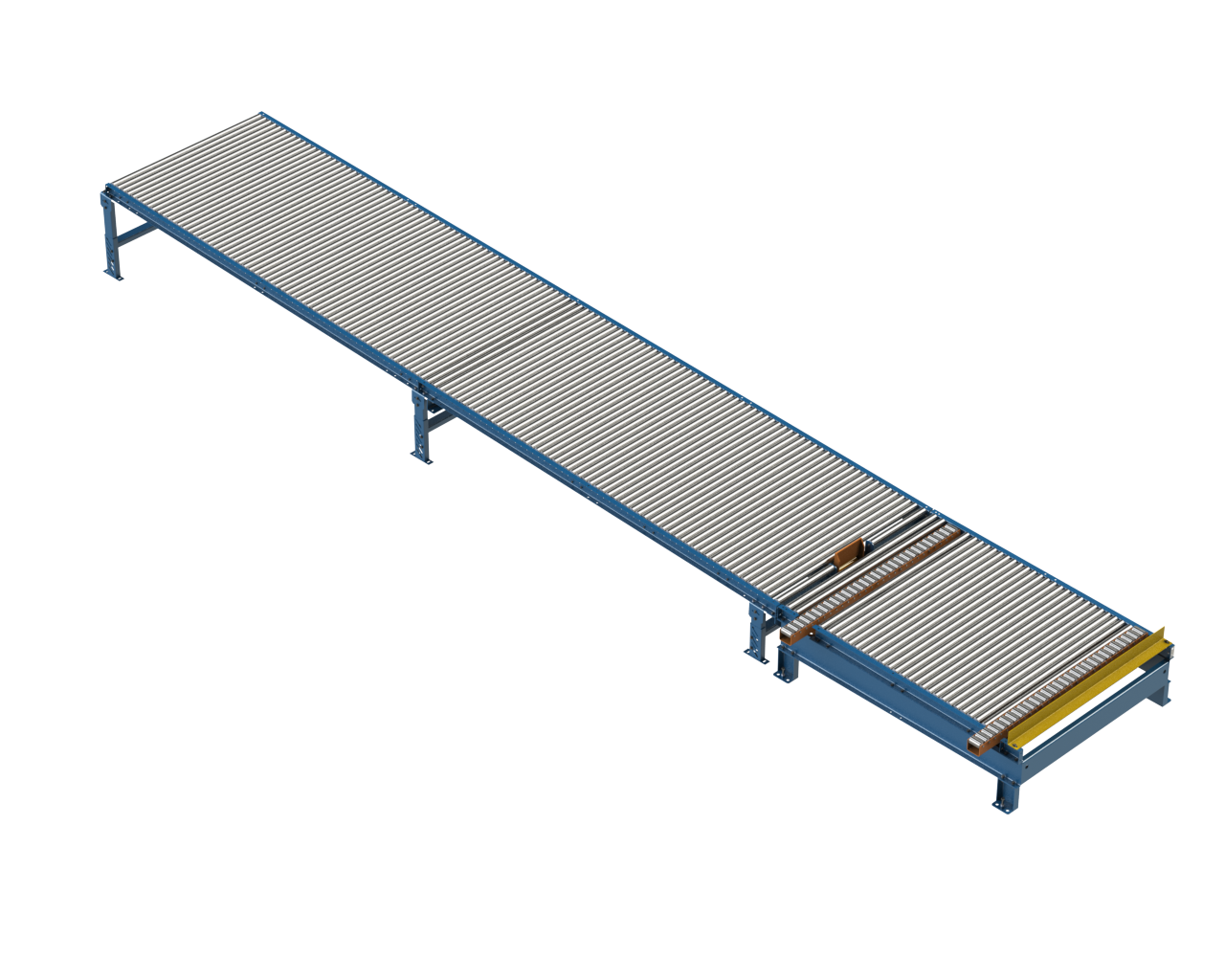

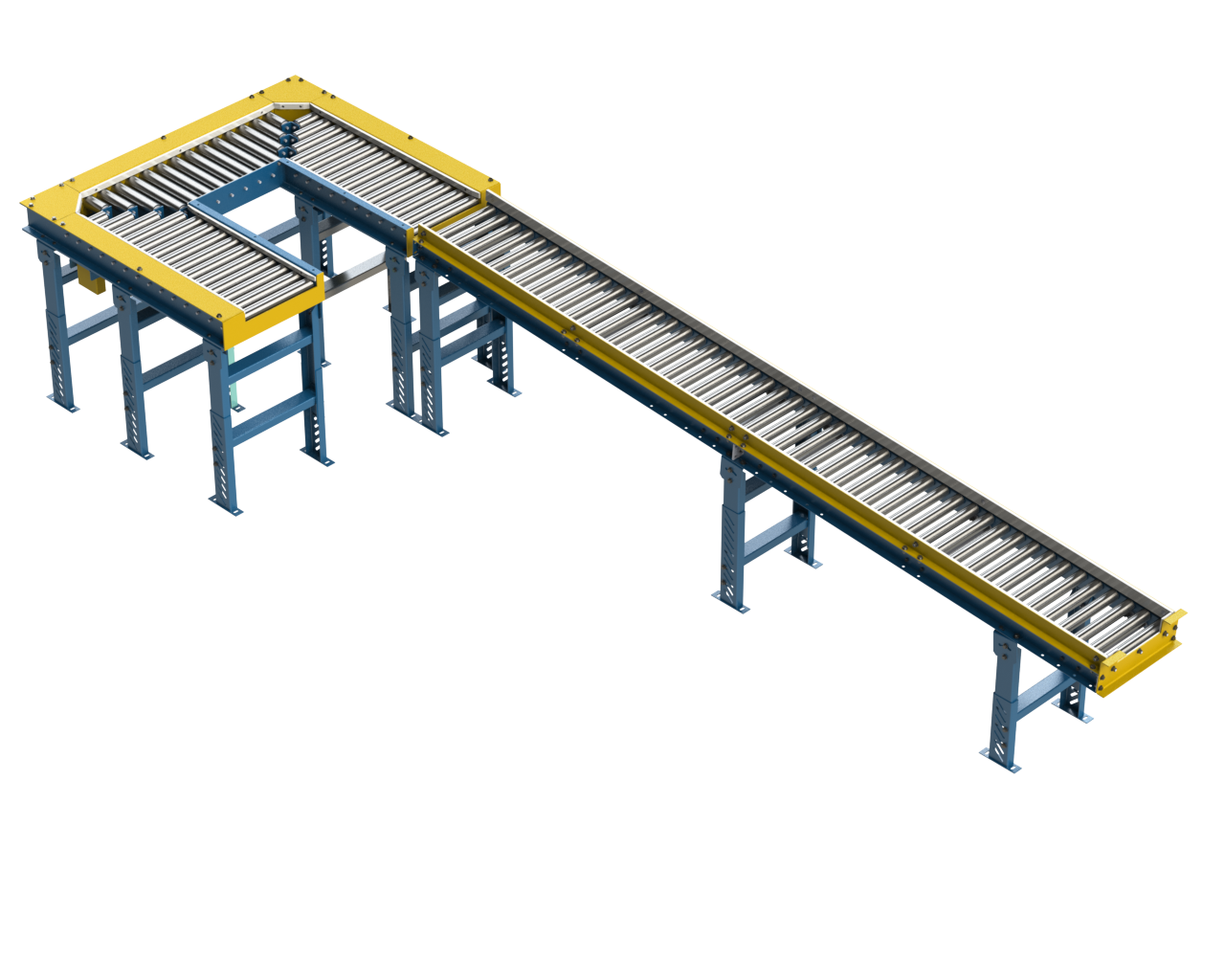

Application: Conveying 48″x48″ Pallets of 55-gallon drums weighing 4,000 LBS. each. Solution: LEWCO provided a combination of pallet handling conveyor, including Chain Driven Live Roller (CDLR), Drag Chain Conveyor, Turntables, and Transfer Cars. In the customer’s initial layout, they had several turntables. After learning more about the application and required rate, LEWCO proposed using Transfer …