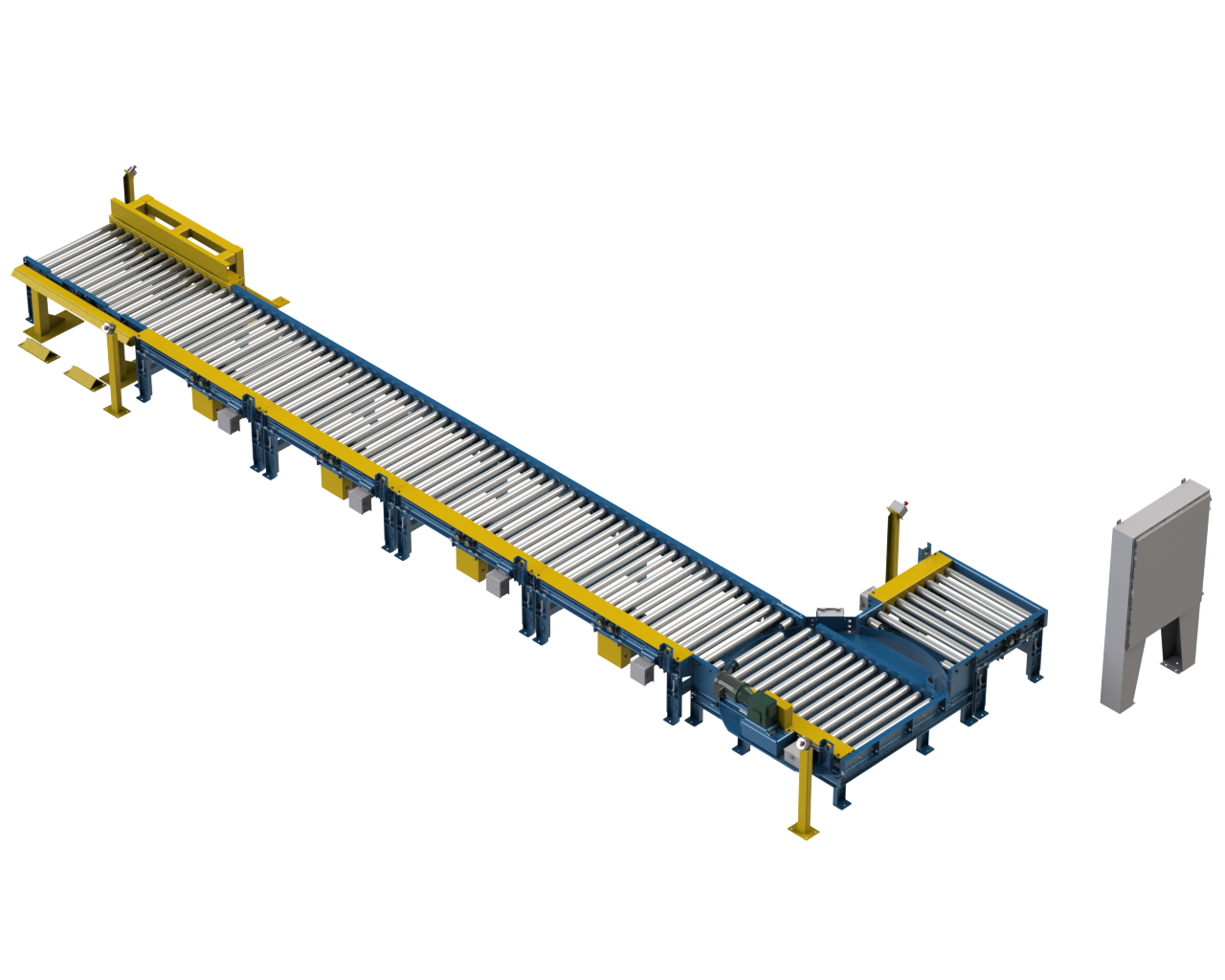

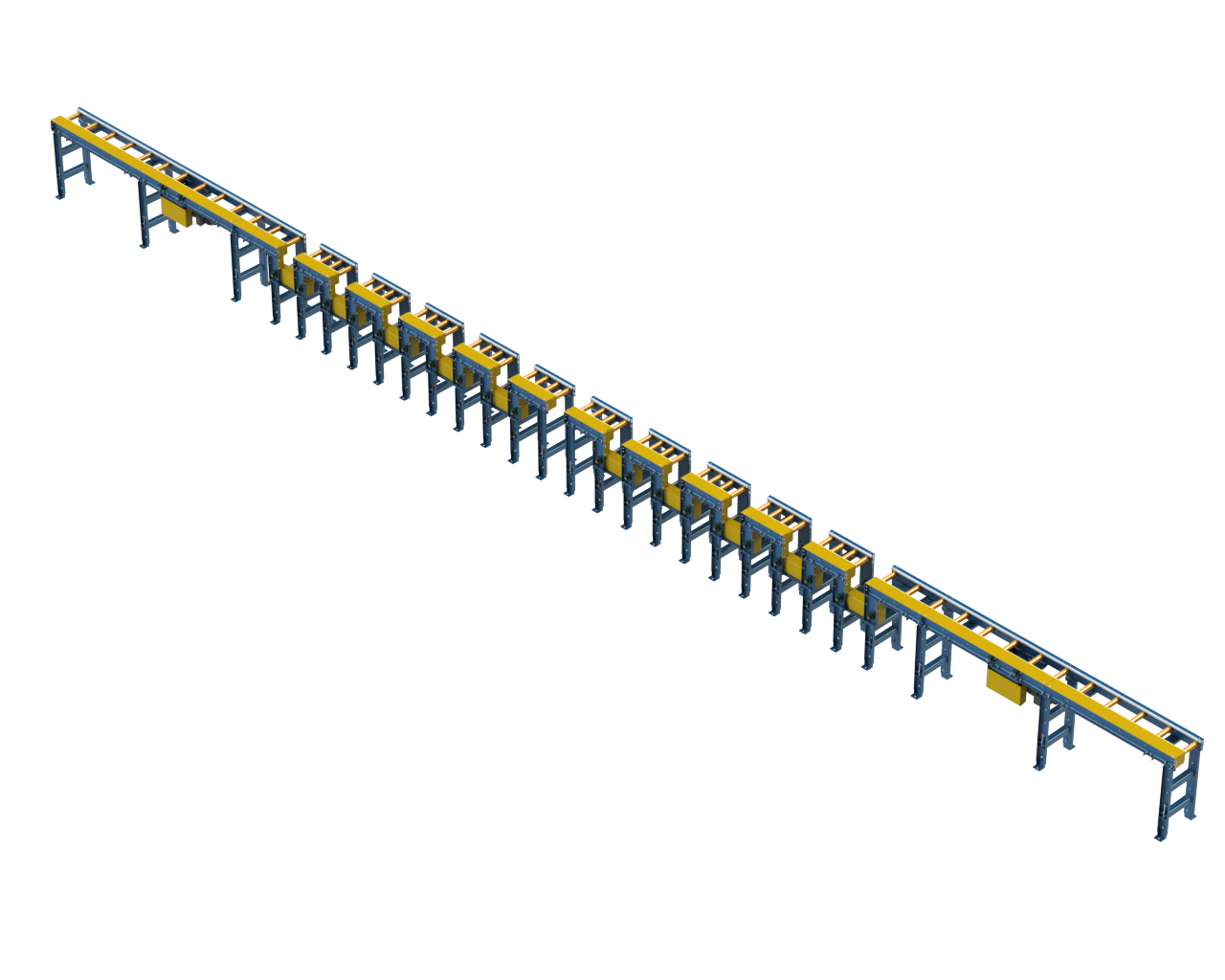

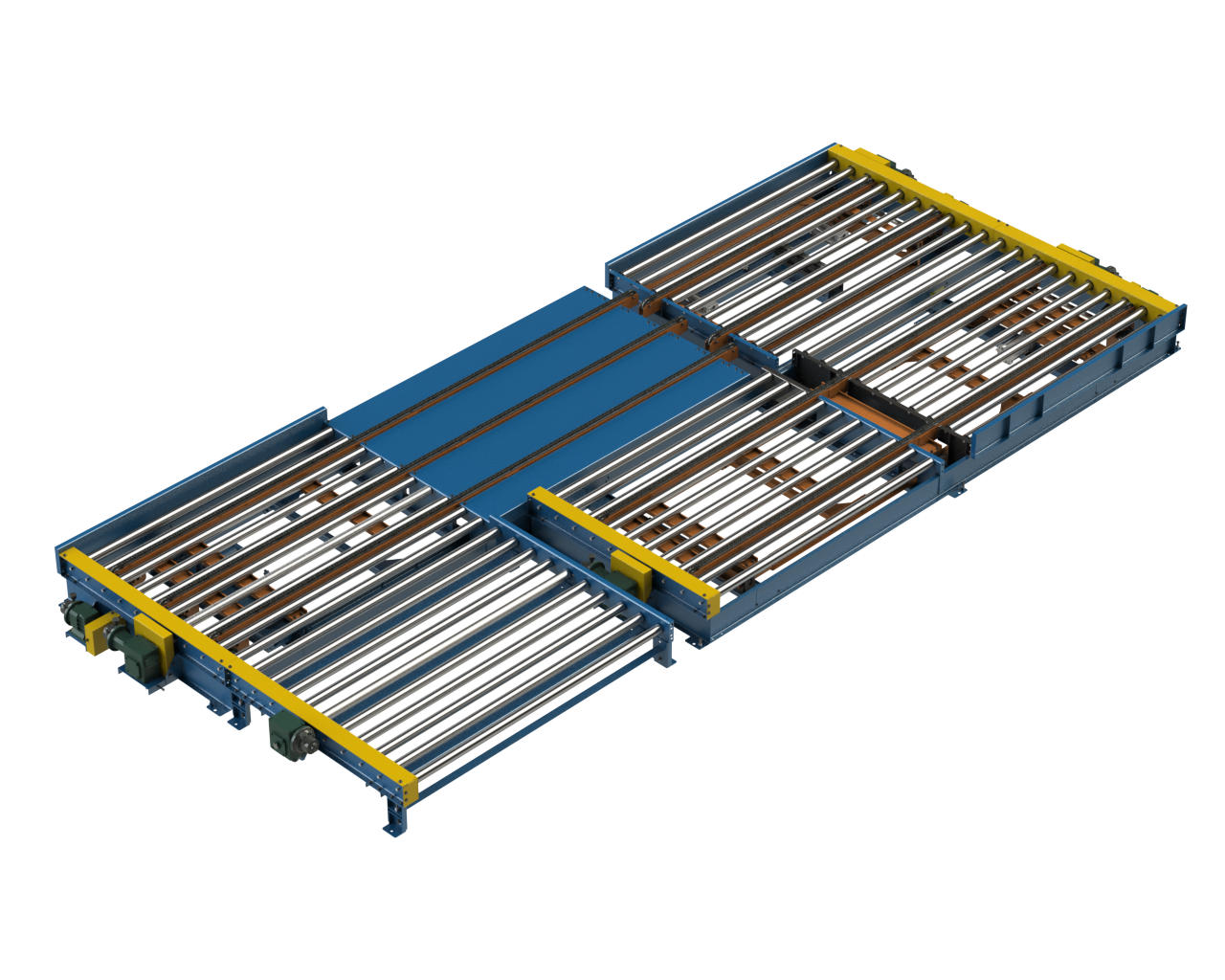

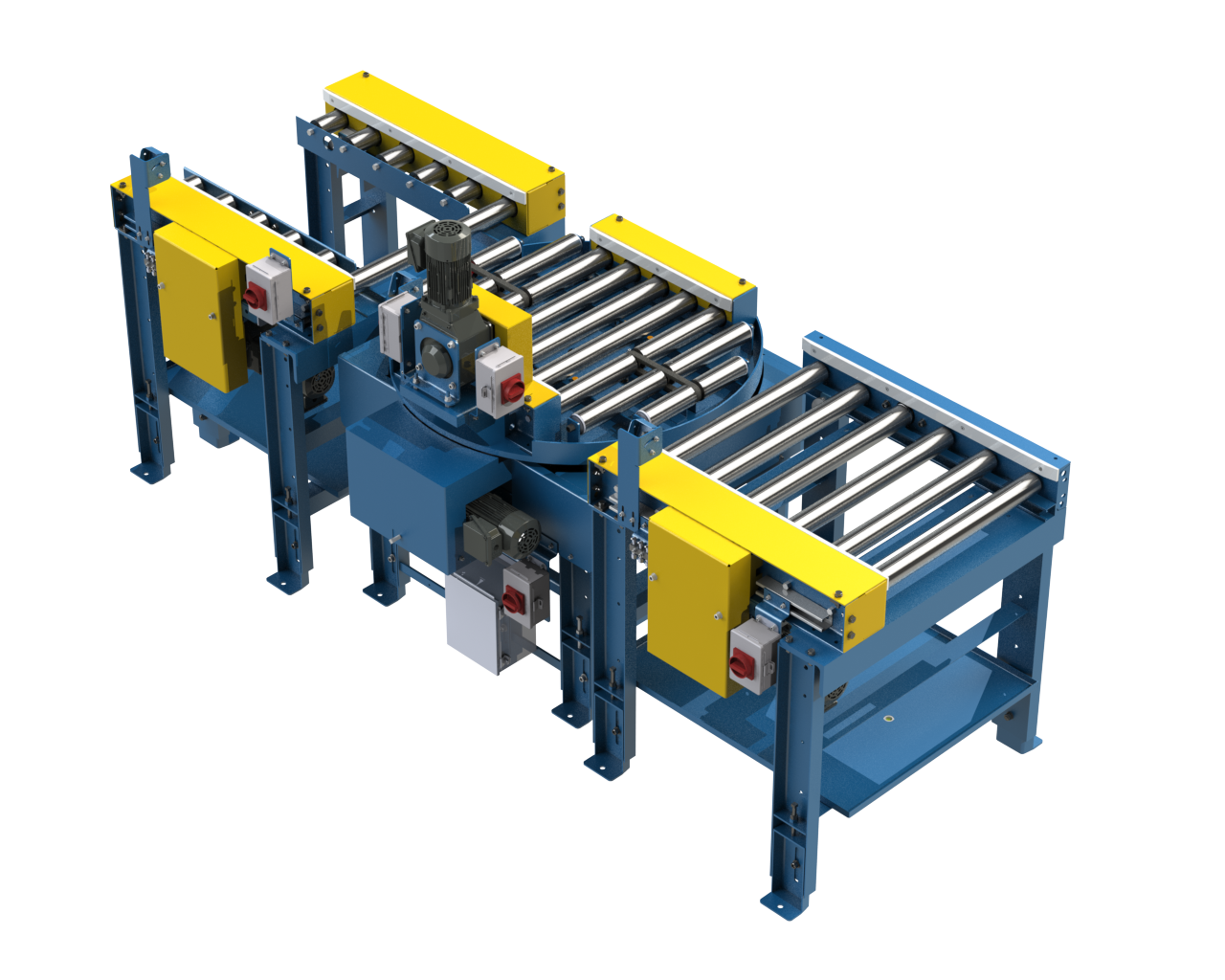

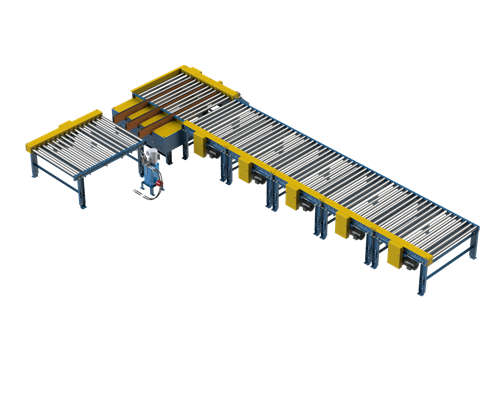

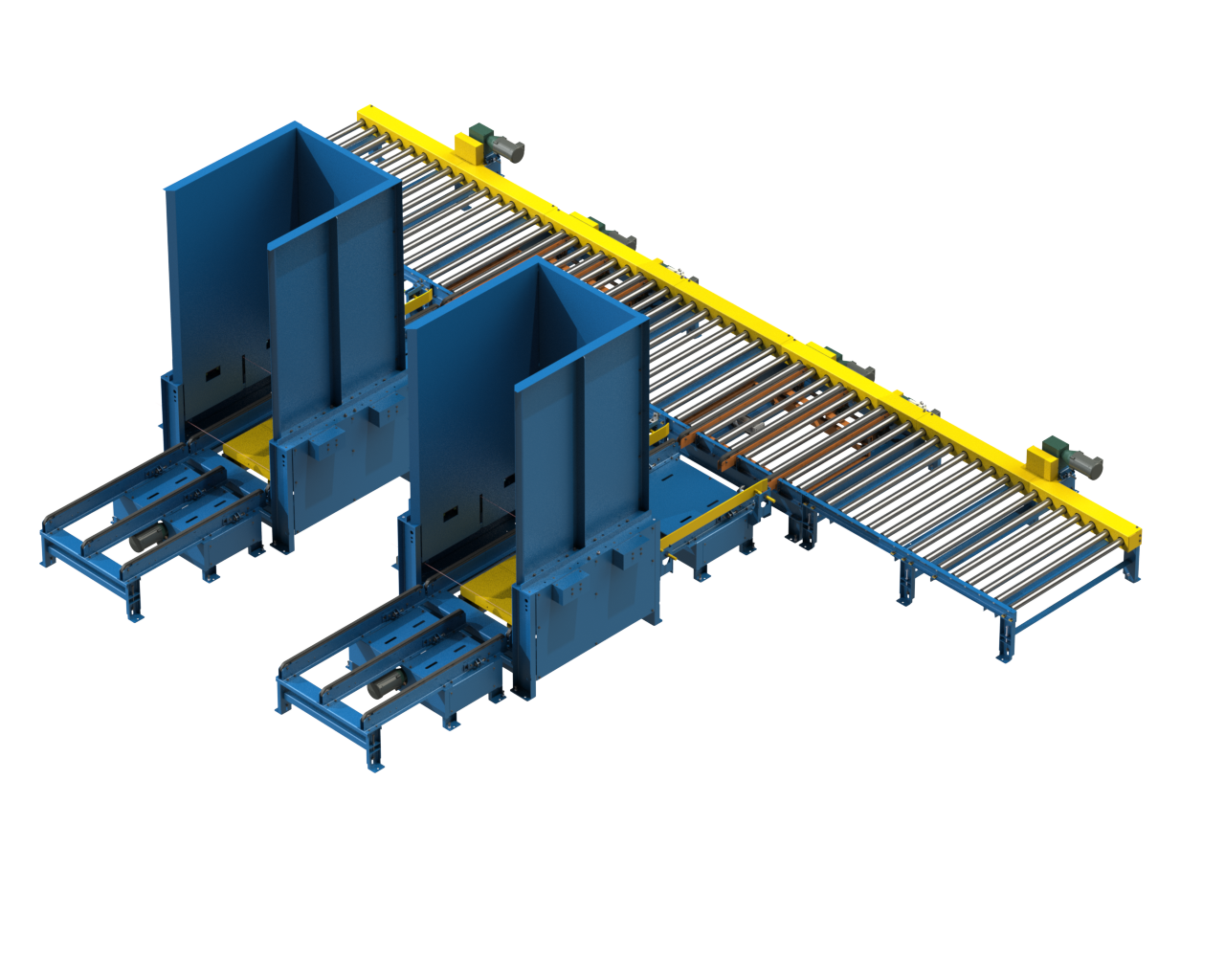

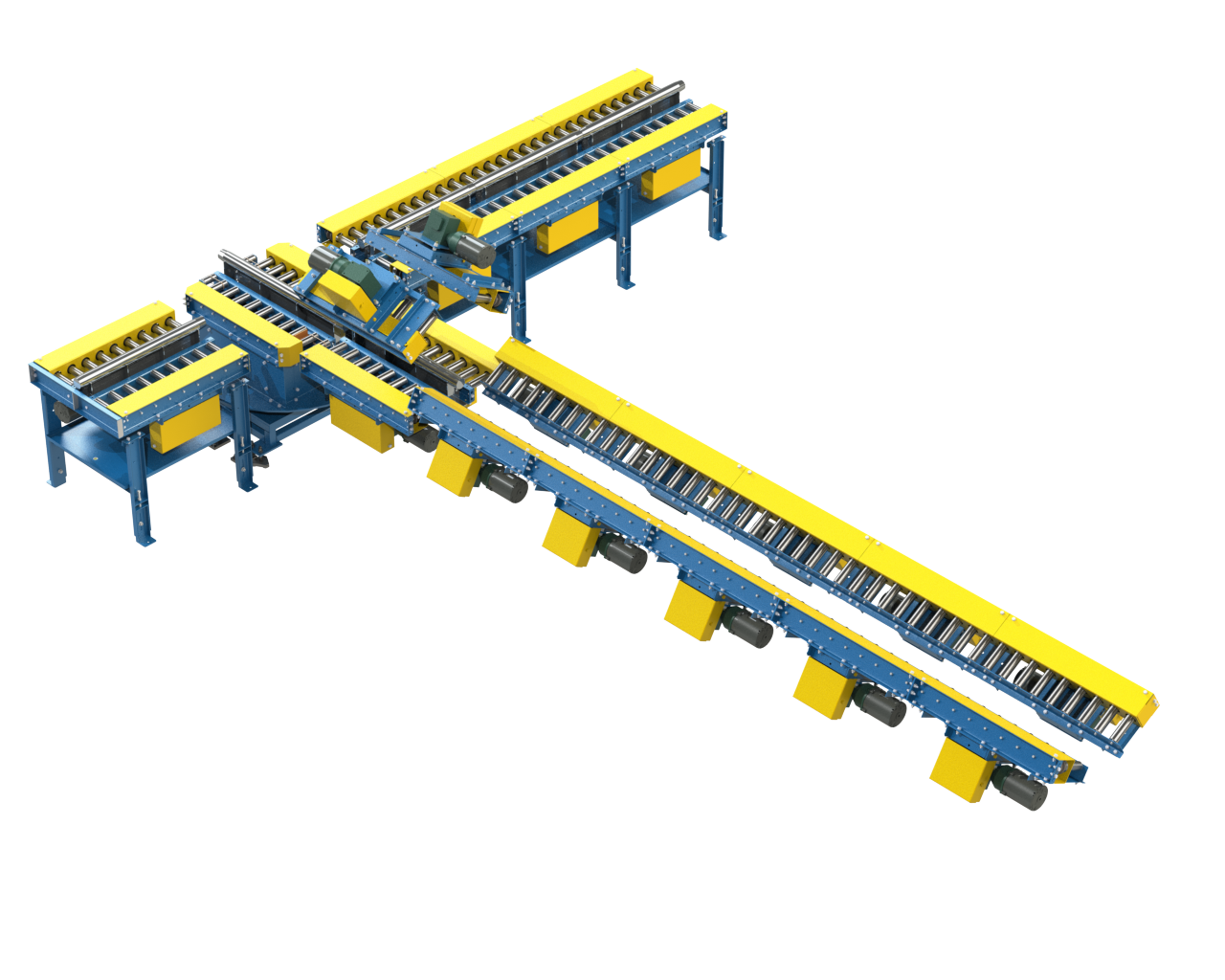

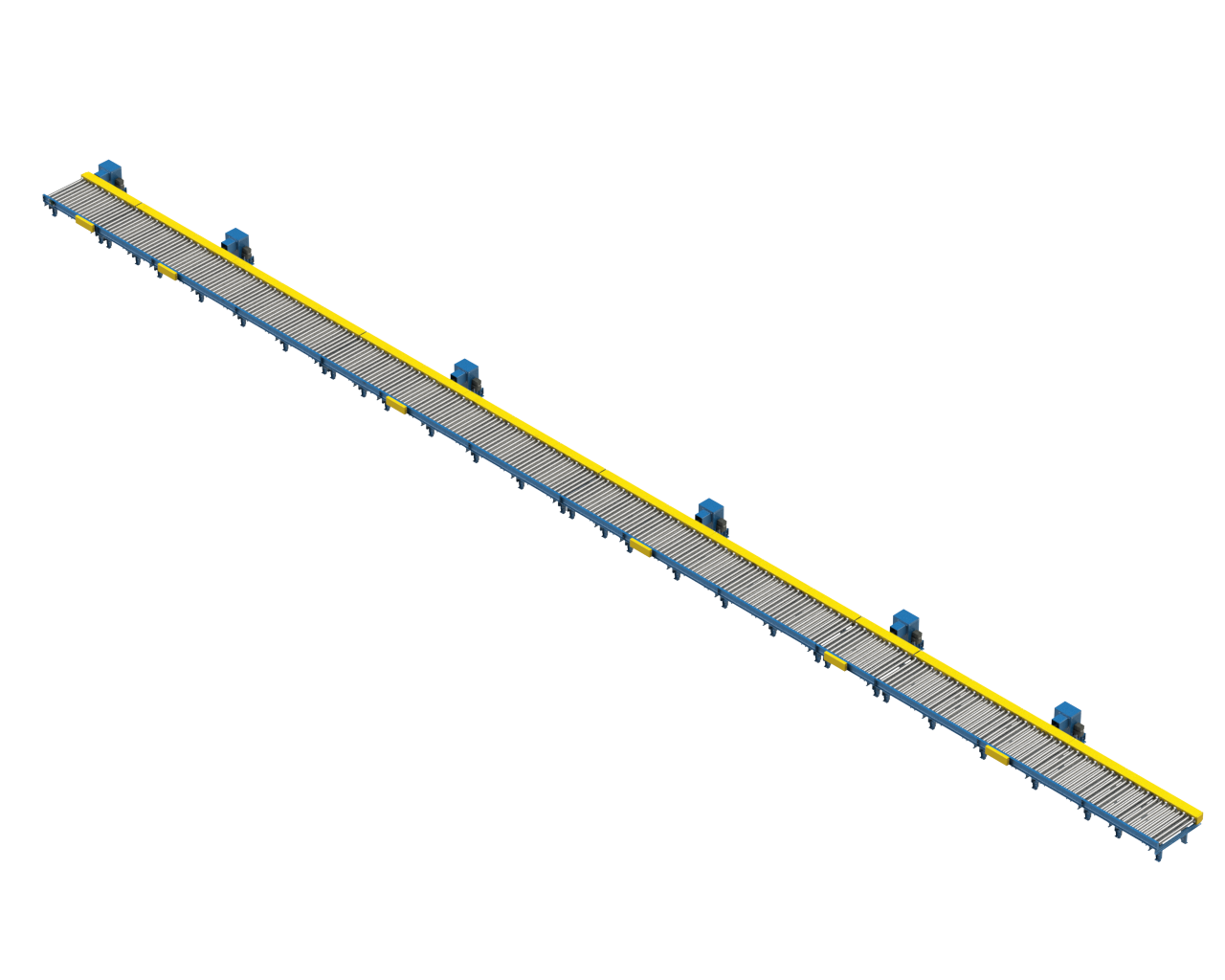

LEWCO Automatic Pallet Buffer for Weld Cell

One of LEWCO’s customers needed to replace an existing manual push gravity system with an automatic powered system. LEWCO engineers worked with the customer to determine the best equipment and layout for the task. Forklifts drop off wood pallets of parts, weighing up to 2,700 lbs each, to stage for a robotic weld cell. Near …