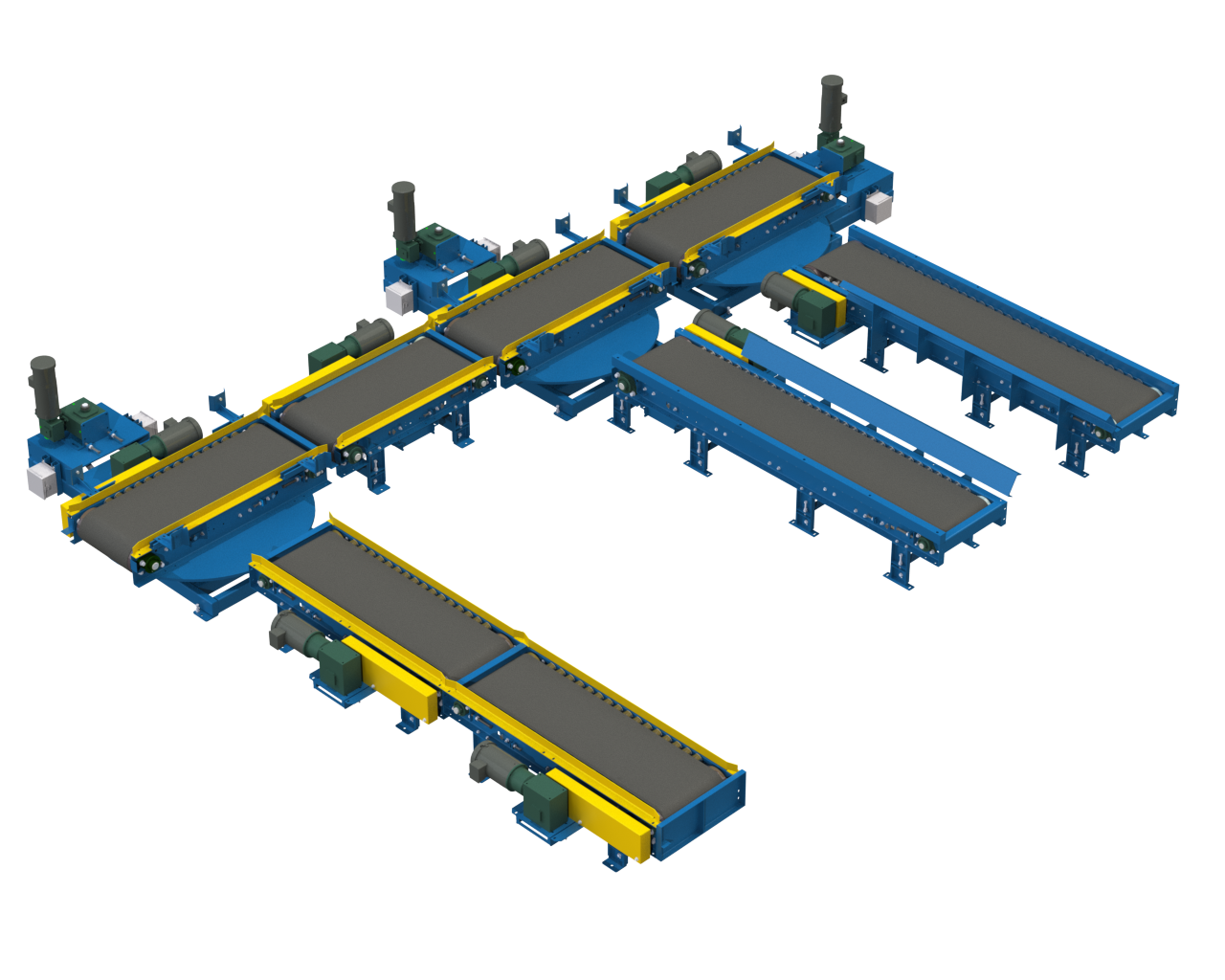

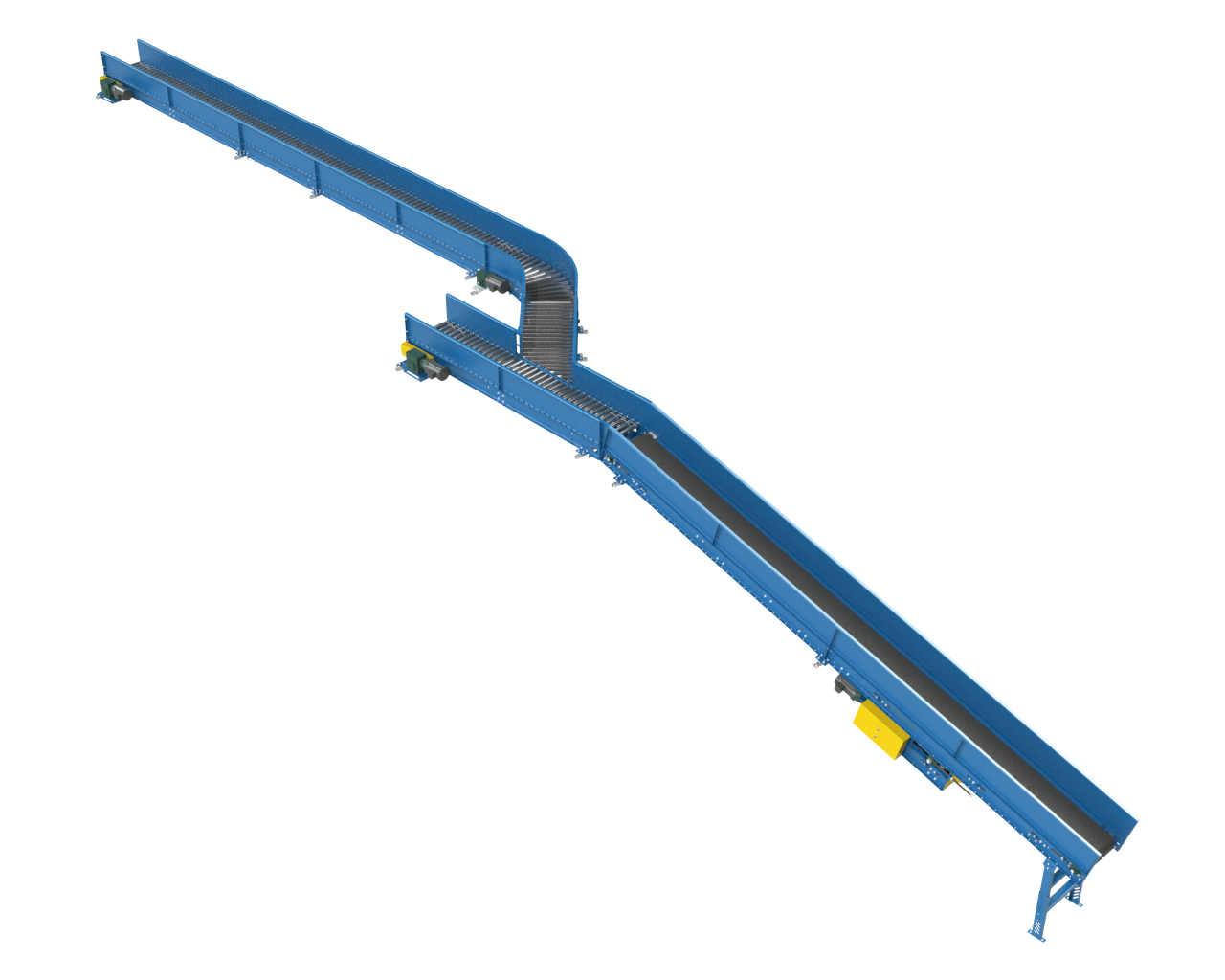

Lewco Retail E-Commerce Distribution Parcel Belt Conveyor

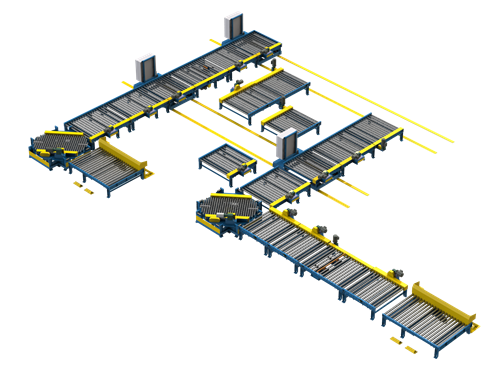

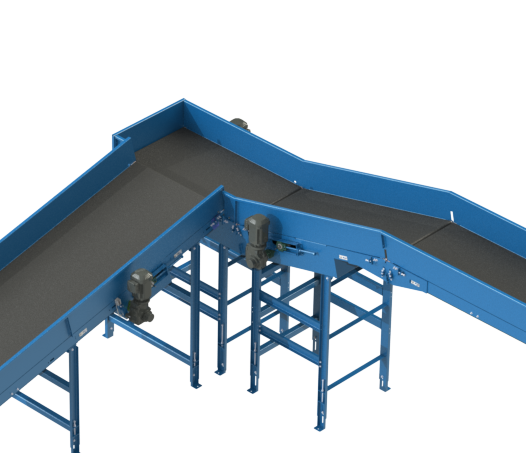

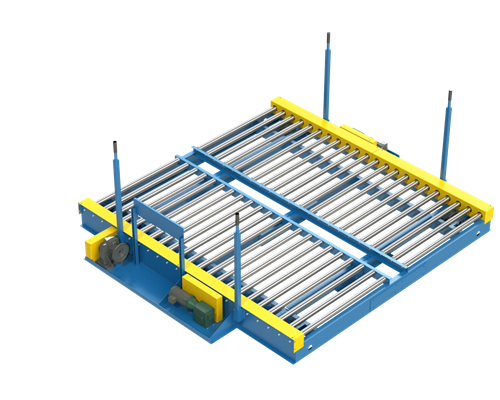

LEWCO recently provided an integrator with a series of conveyors from our LEWCO RED line which is specifically designed for the Retail E-commerce Distribution industries. These units are part of a manual sort center for the fulfillment services of a well-known internet-based retailer and were designed to handle both cartons and smalls/flats of various sizes. …

Read More “Lewco Retail E-Commerce Distribution Parcel Belt Conveyor”