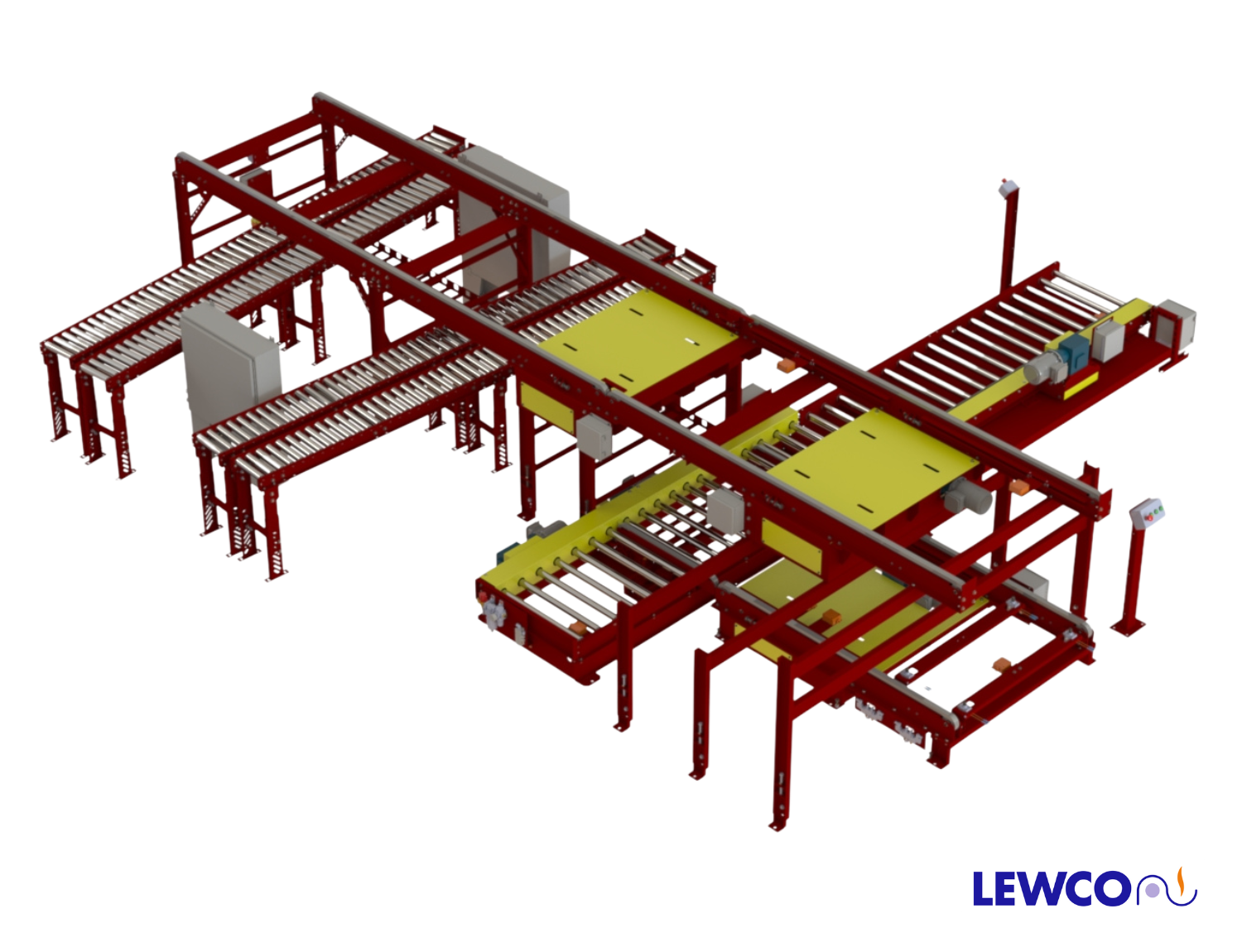

Heavy Loads, Light Work: The Future of Pallet Conveying

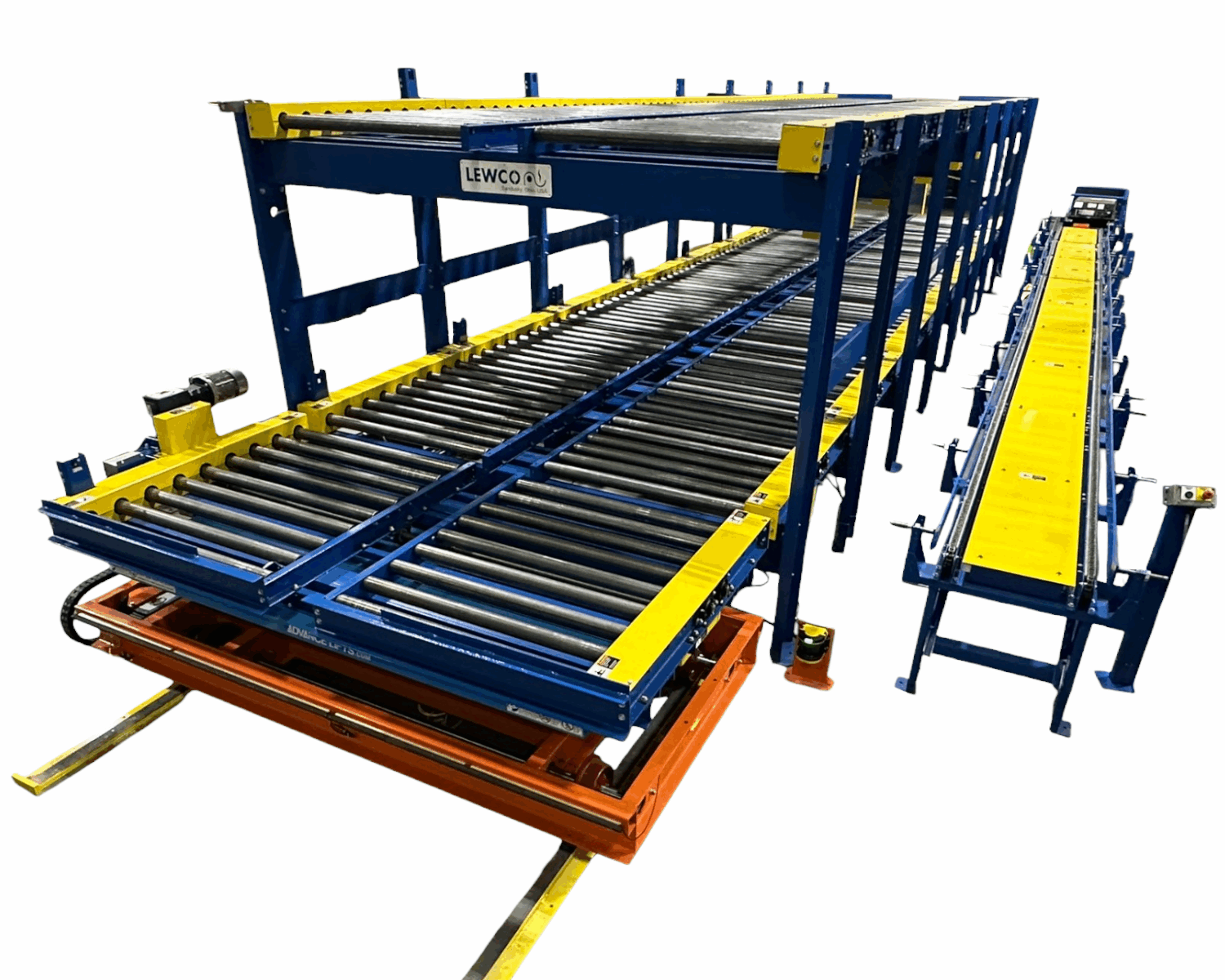

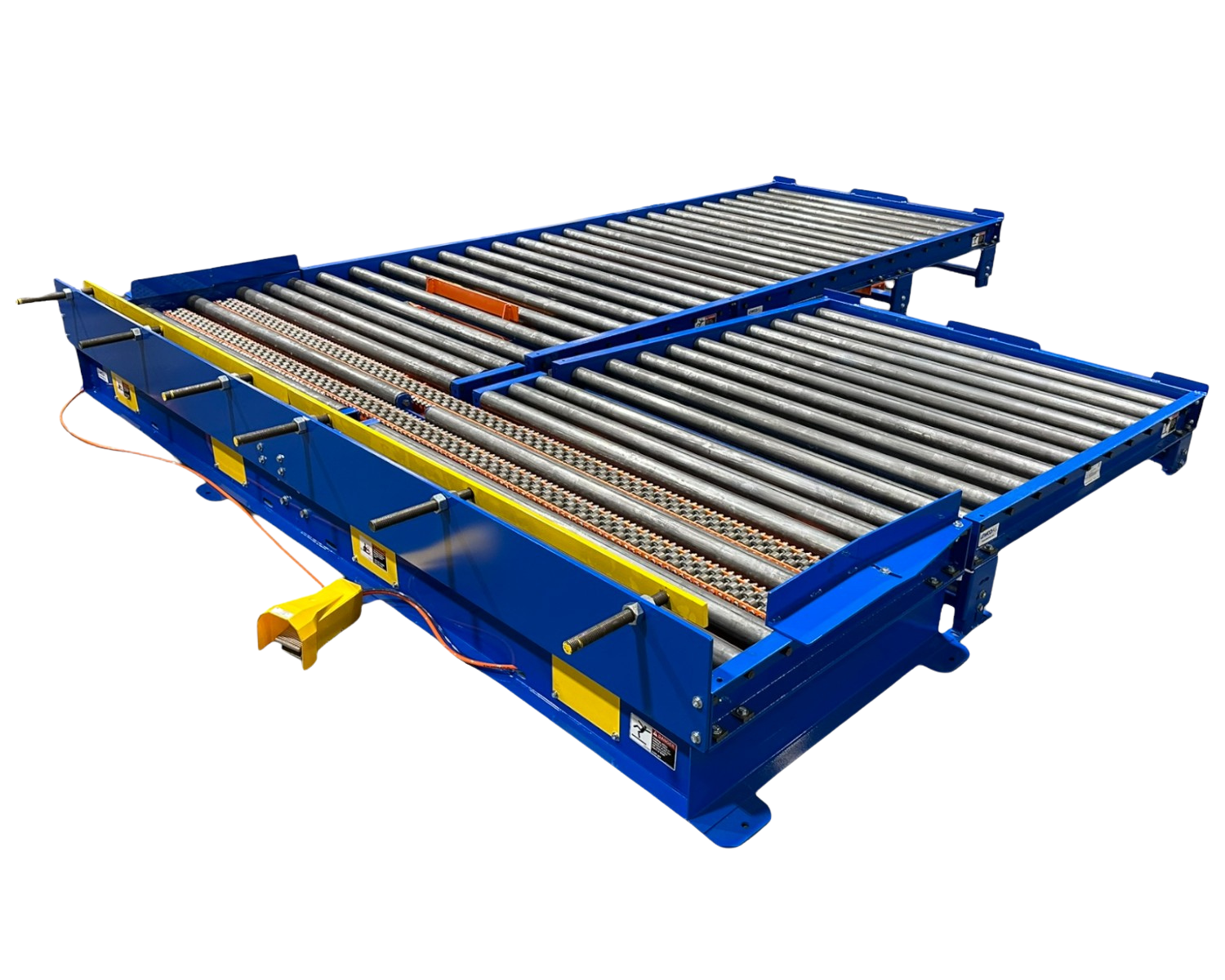

An integrator approached LEWCO, Inc. with a pallet conveying challenge. The customer needed a system to receive pallets from multiple vendors, store them until needed, and then break them down into multiple consolidated shipments for their own customers. LEWCO’s role was to design a solution that could: Buffer incoming pallets for storage. Create picking loops …

Read More “Heavy Loads, Light Work: The Future of Pallet Conveying”