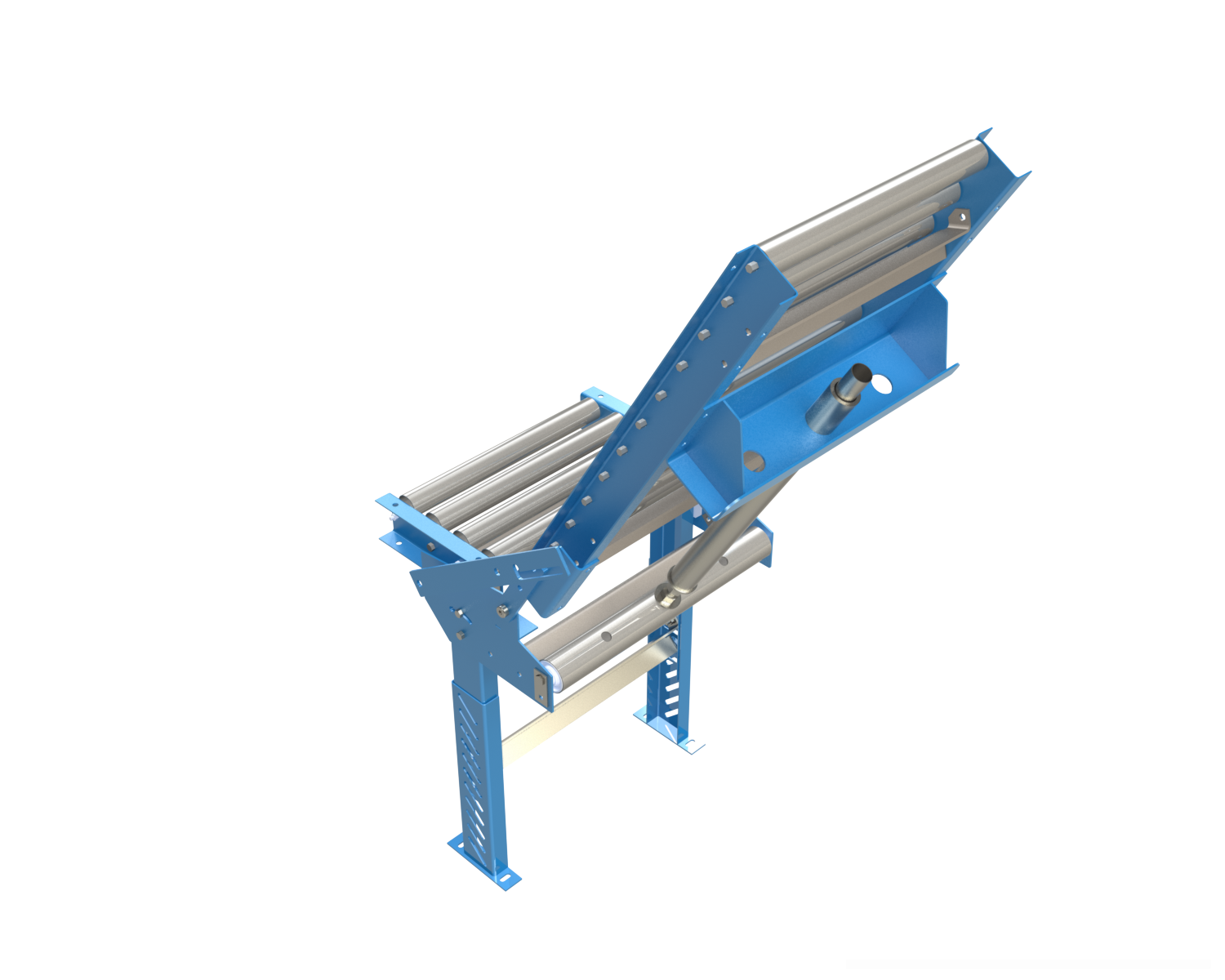

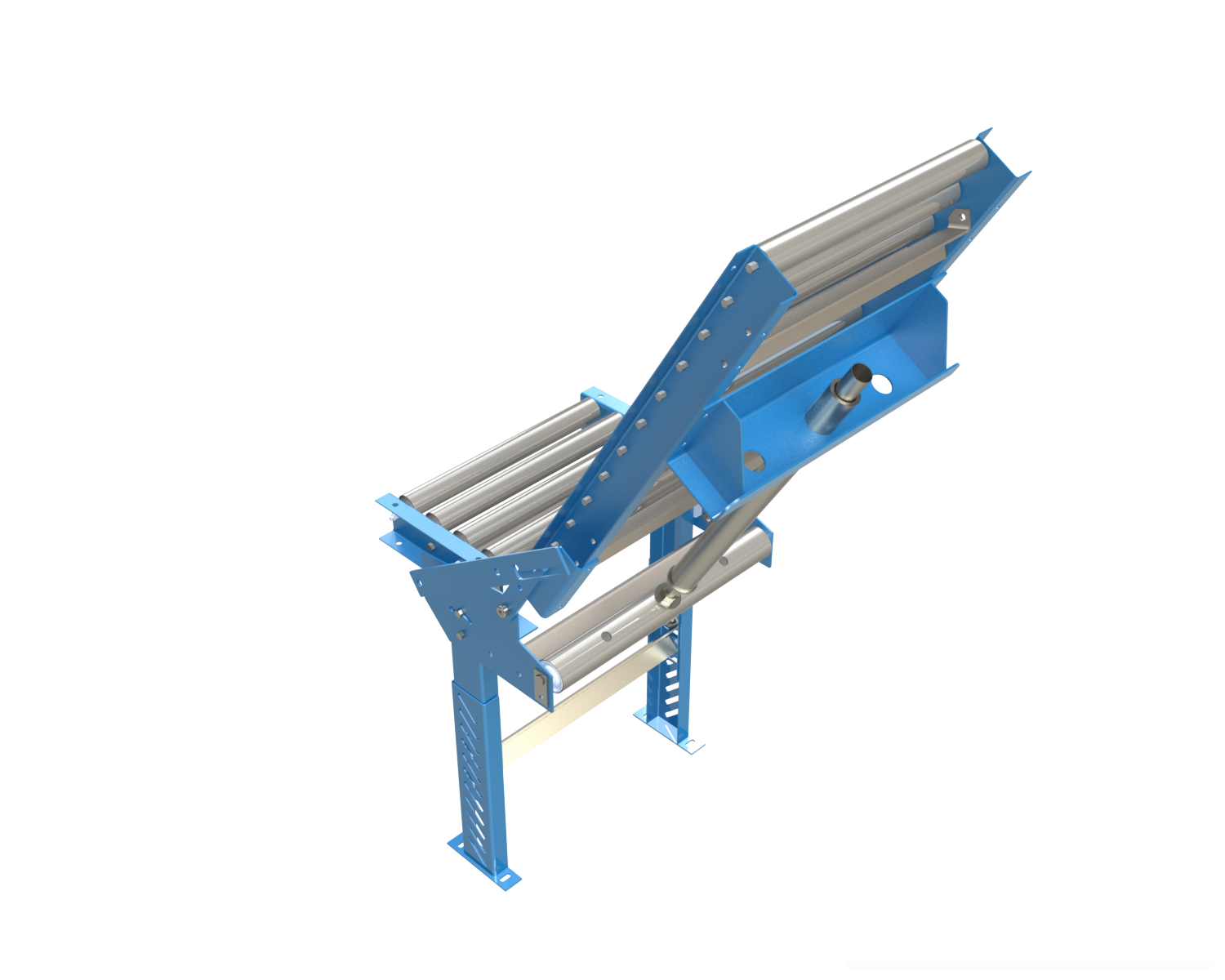

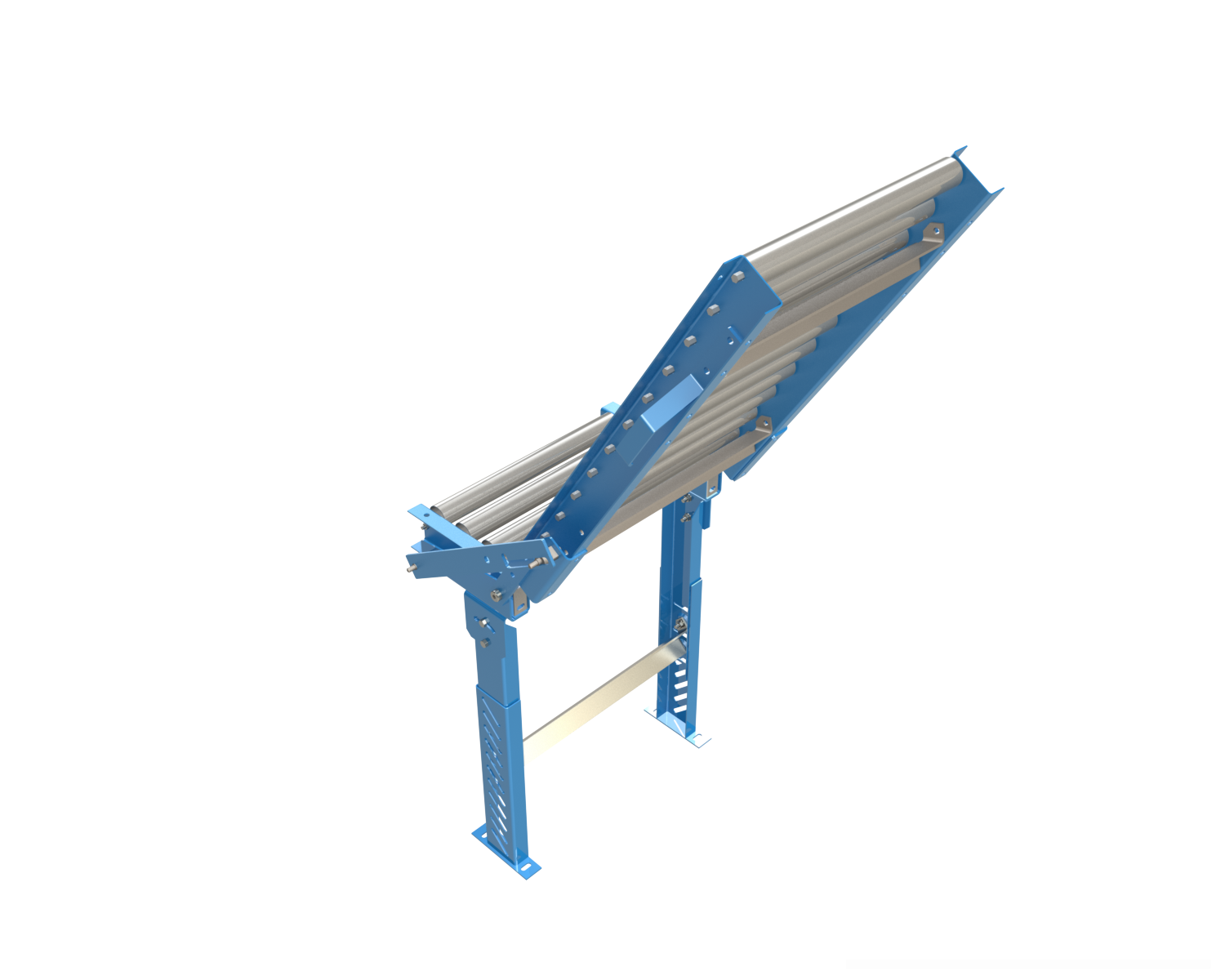

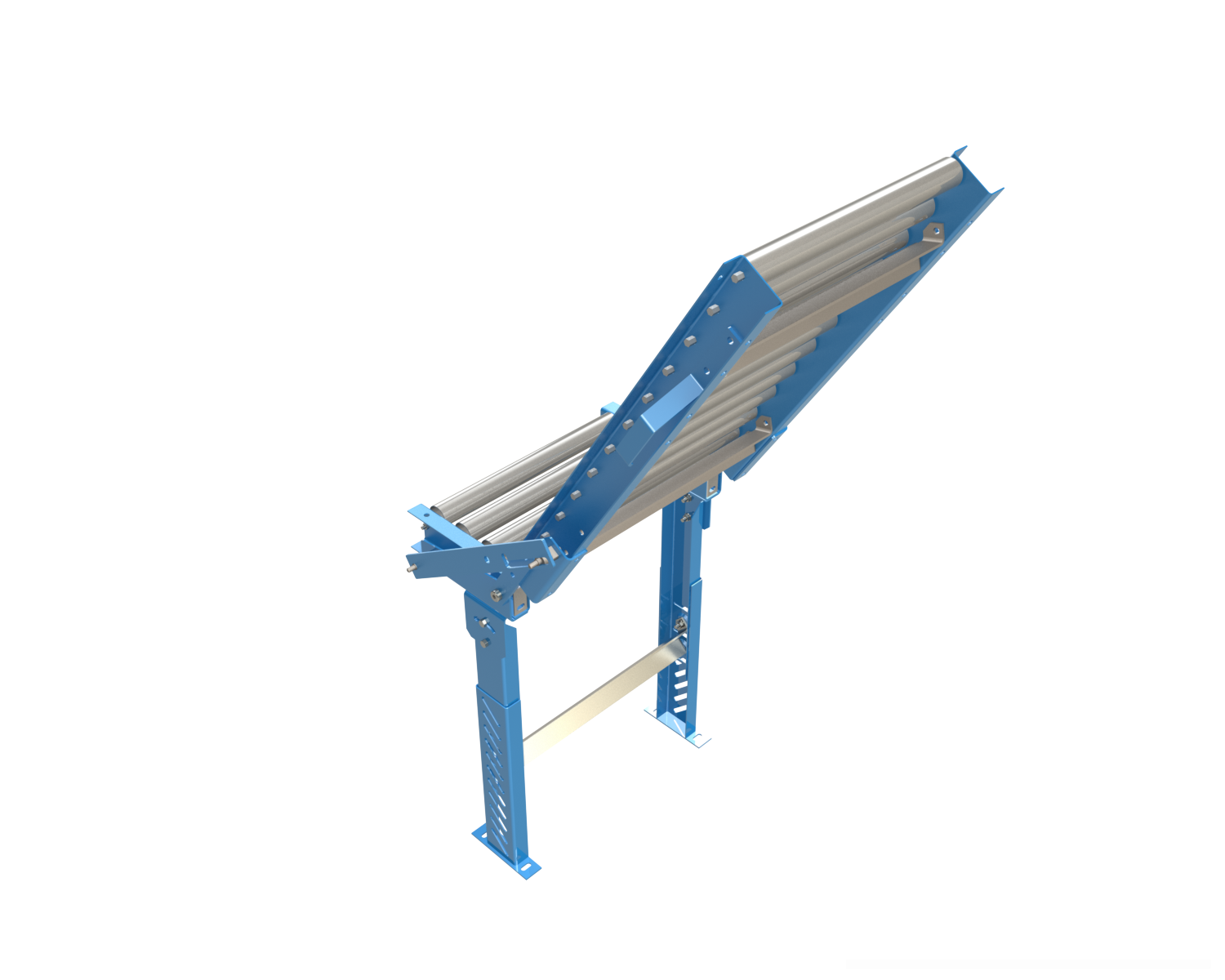

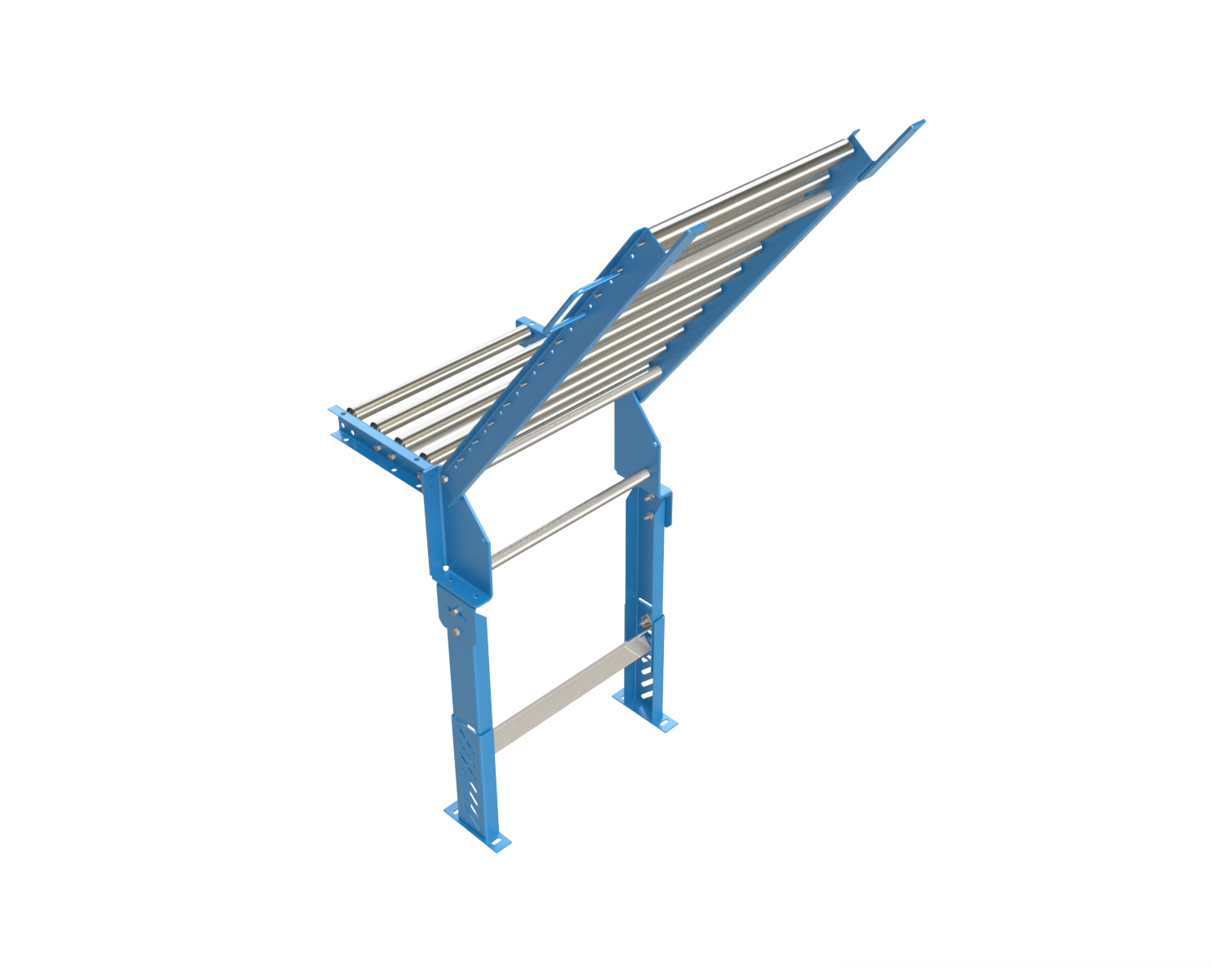

HS1912 – HINGE GATE, SPRING ASSISTED, 1.9″ DIA. x 12 GA. ROLLERS

Model HS1912 spring assisted hinged gate provides an opening for convenient access to either side of a conveyor line. Low maintenance design, can be easily adjusted to lift with a minimal amount of effort.