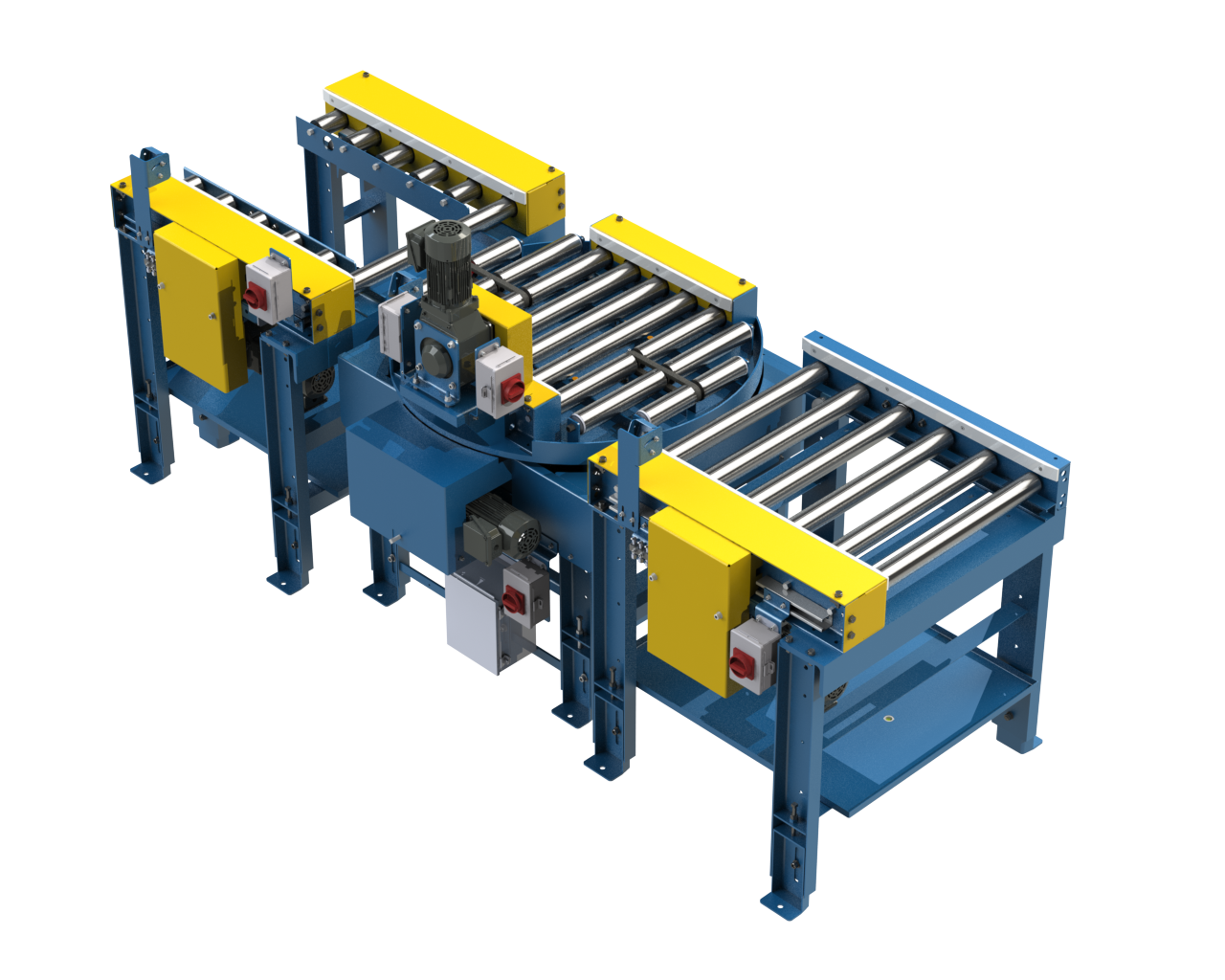

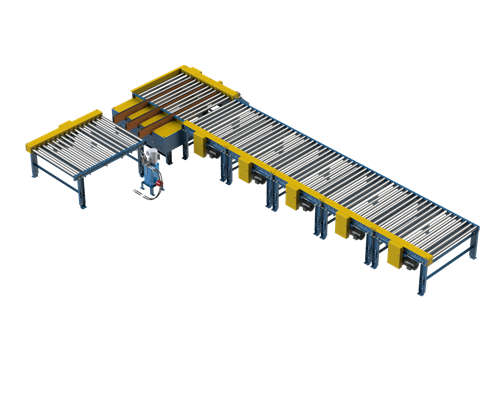

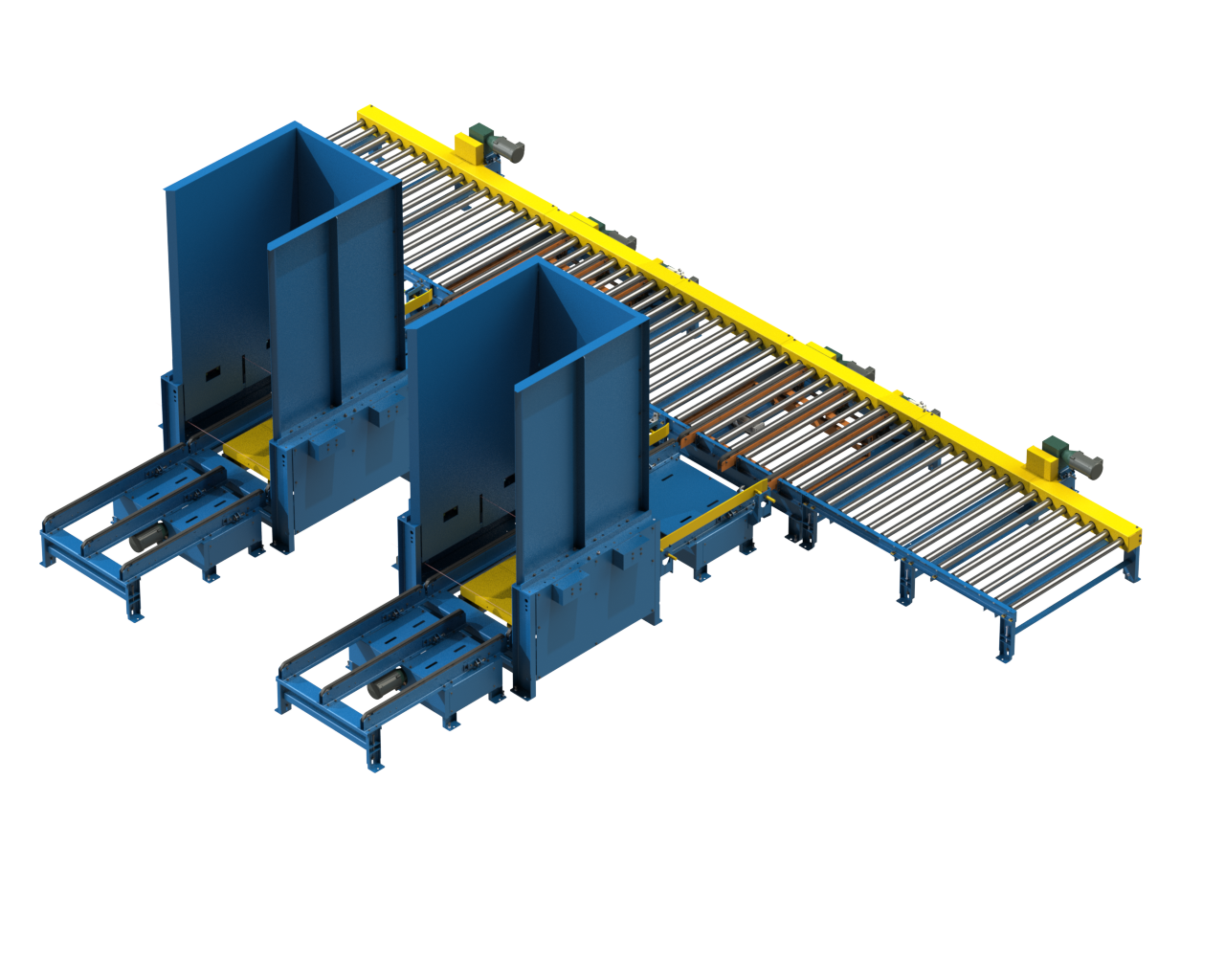

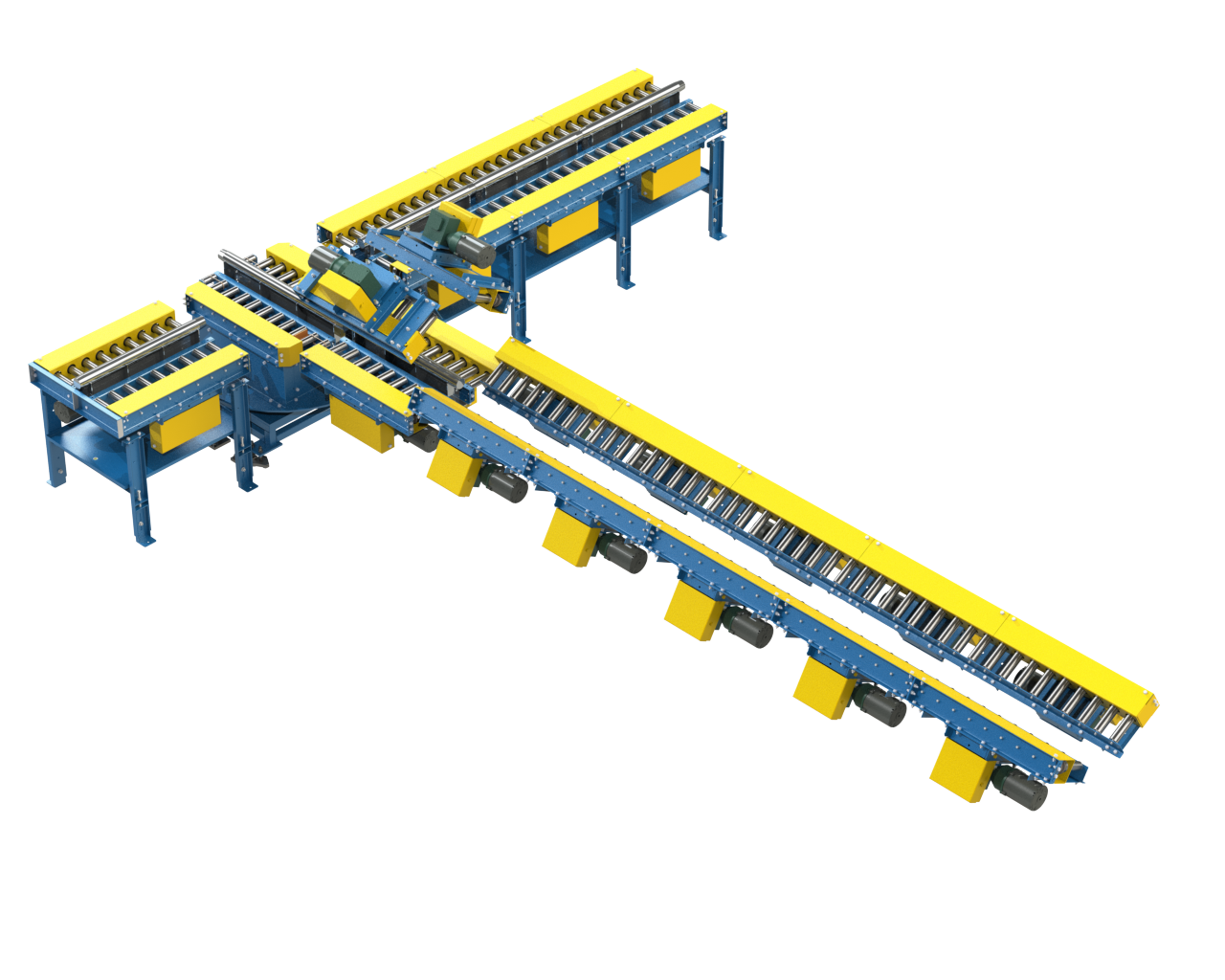

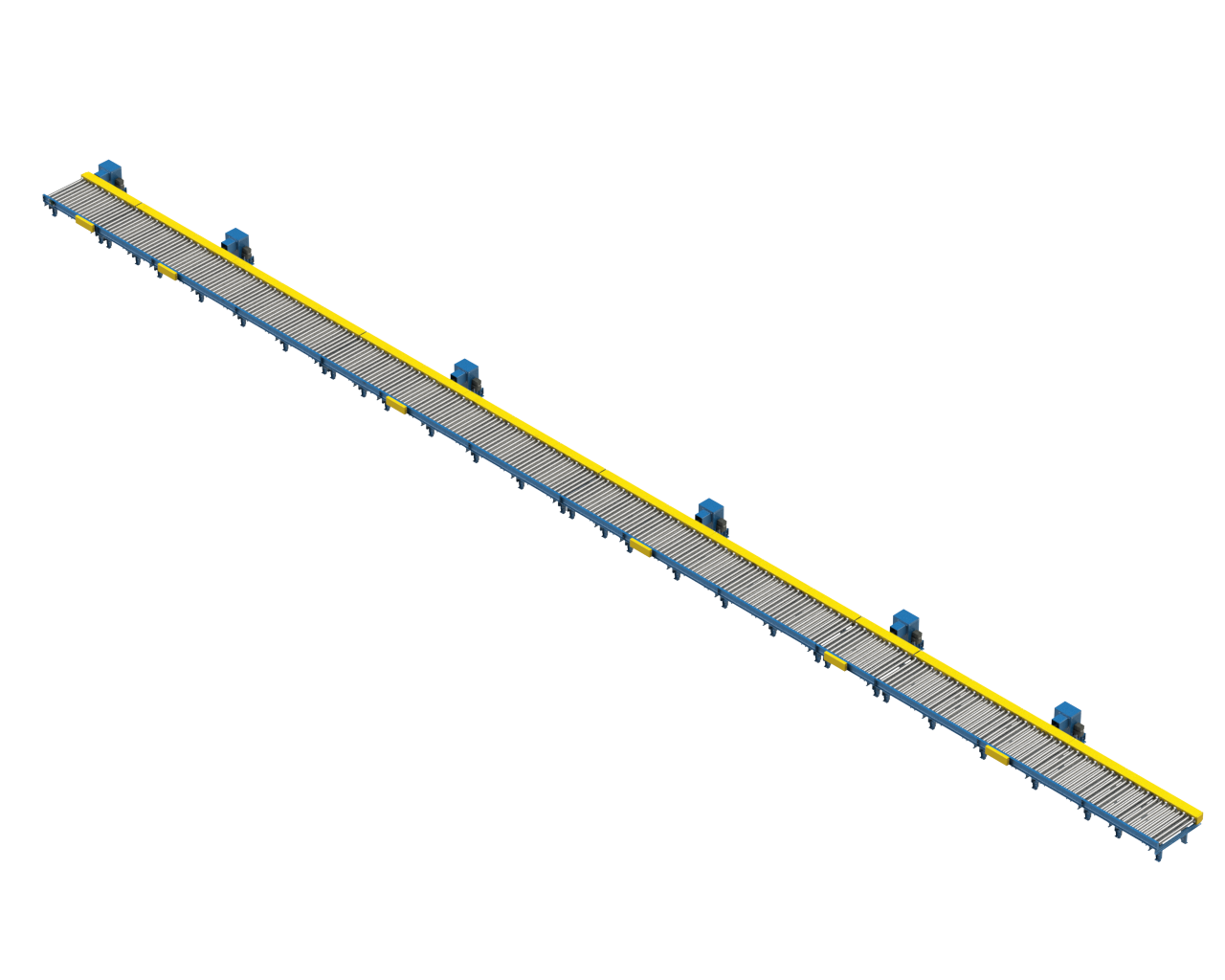

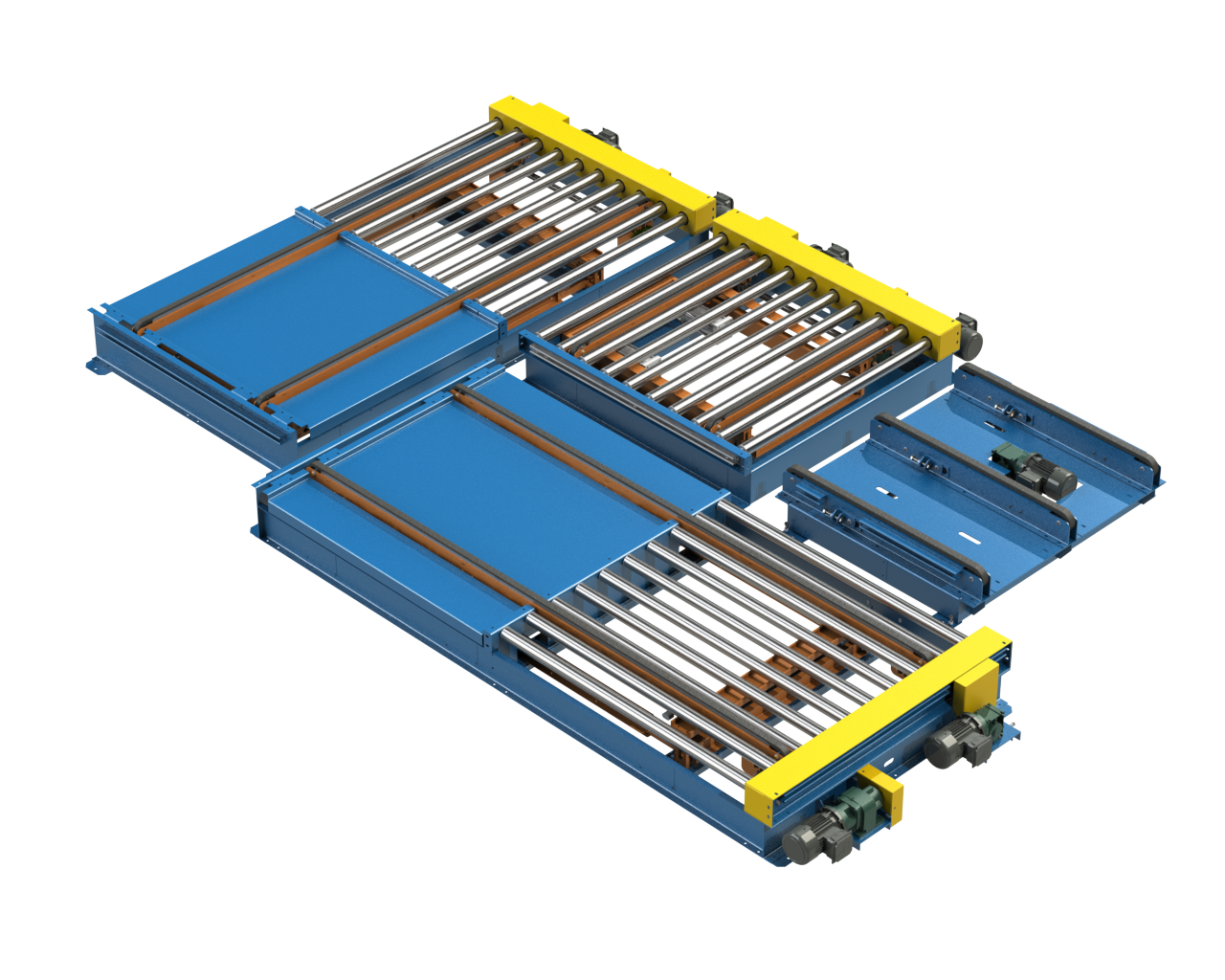

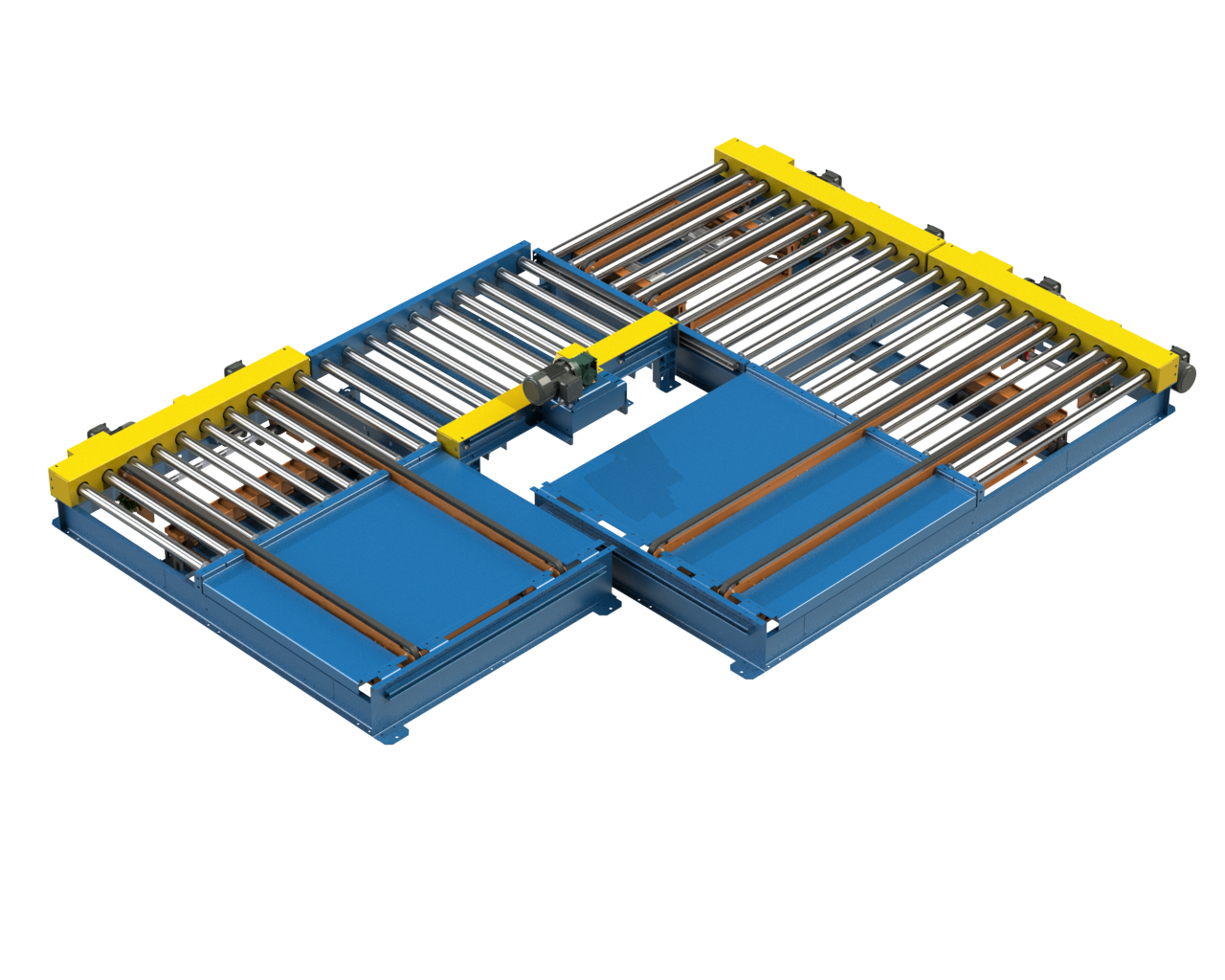

LEWCO Furnace Support Conveyors

LEWCO recently completed some equipment that may interest you. One of our customers needed support equipment for their furnace line, so LEWCO engineered heavy duty chain driven live roller, chain transfers, and a turntable for their heat-treat trays. Loads were a maximum of 1,000 lbs per 24” x 24” tray. The new conveyors had to …