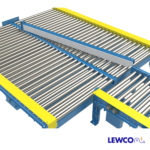

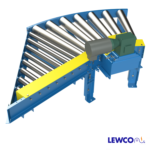

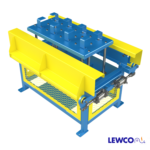

In the material handling industry, pallet handling presents unique challenges which have been addressed with LEWCO Professional Grade pallet handling equipment. We offer a wide variety of conveyor types which easily integrate with automation like robotic operations, packing and shipping operations, ASRS installations, stretchwrappers, AGVs, and more. Robust construction stands up to the daily abuse from skids and pallets, and equipment can be set up for transportation, indexing accumulation, or zero-pressure accumulation. Pallets are usually conveyed on CDLR (Chain Driven Live Roller) and Chain Conveyor, depending on pallet orientation. Chain transfers or roller transfers are used to facilitate 90 degree changes in direction. If other degrees of rotation are needed, or if pallet orientation needs to be maintained, a conveyor on a turntable can be used instead. A pallet stacker, destacker or dispenser can be added to a system to minimize forklift trips to the beginning or end of a system. Multiple storage lanes can be accessed by using a transfer car along one or both ends.

Unit loads are another area of LEWCO expertise. Boxes, cartons, trays, and other products types of all sizes can be handled in much the same manner as pallets, but on a smaller scale. Other types of conveyor like fabric belt, modular plastic belt, dense small roller sorters, etc. are available to complete a functional conveyor system. Controls can be supplied to augment the system and save installation time.