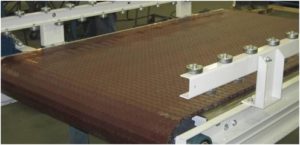

LEWCO Modular Plastic Belt Conveyor

Utilizing Intralox modular plastic belting, LEWCO recently supplied a major tire manufacturer with a high speed decline conveyor. The application required a robust design capable of starting and stopping tires weighing as much as 80 pounds every 2.4 seconds, at speeds as high as 160 feet per minute!

Working closely with Intralox engineers to design a robust conveyor for the environment, LEWCO’s finished product exceeded expectations for the 24/7, high duty cycle application.

This conveyor is just one example of modular plastic belt conveyors LEWCO has to offer for a wide variety of applications.

Besides tire handling, modular plastic belt conveyors are available to service applications ranging from stainless steel wash-down, to package and parcels, to handling heavy loads with irregular bottoms, and a host of opportunities in between.

The belting is driven by a series of sprockets on the head and tail shaft. Because of the positive drive, no belt tracking is required. In the event of damage, the segmented sections are east to replace. This conveyor is tough, easy to run, and easy to maintain.

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.