LEWCO Dip Tank Conveyor

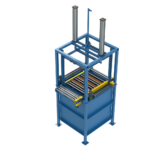

LEWCO often has the opportunity to build conveyors for special purposes, usually as part of a larger system. Recently LEWCO built this conveyor which was to be repeatedly submerged into a cooling tank. The cooling tank water was around 150 degrees F. Although the conveyors did not need to run while submerged, careful design consideration was required by engineering.

Since the drives would not survive in a submerged state, LEWCO designed articulated linkages to allow the customer to mount them at the top of the framework, which would not be under water. Air prep and solenoid valves were also located above, with piping run to the air devices below. Graphalloy bearings were used due to their resilience under water. The cage frame weldment was also built by LEWCO.

LEWCO engineers worked with the customer to arrive at a design solution which was robust enough for the process without surpassing the budgetary constraints.

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.