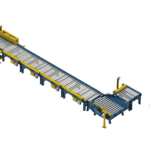

LEWCO Automatic Pallet Buffer for Weld Cell

One of LEWCO’s customers needed to replace an existing manual push gravity system with an automatic powered system. LEWCO engineers worked with the customer to determine the best equipment and layout for the task.

Forklifts drop off wood pallets of parts, weighing up to 2,700 lbs each, to stage for a robotic weld cell. Near the end of the system, the pallets are rotated 90 degrees to present parts properly to the robot.

LEWCO engineered, tested, and shipped full controls with this conveyor system, including a main control panel and remote operator pushbutton stations.

This system enabled the customer to reduce inventory touches and streamline their process. What can LEWCO do for you today?

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.