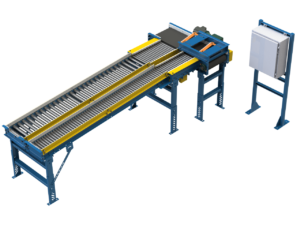

LEWCO Diverter Arms and Modular Plastic Belting Conveyor

An automotive manufacturer was building a couple of alternately sized product, being fed at a 1:1 ratio into a parts washer. Upon exiting the washer, the parts needed to be sorted by size into two lanes. Product throughput peaked at 10 parts per minute.

The product had residual moisture on it from time to time.

Space was at a premium, and of course cost justification was tight.

Rather than sensing product size and causing an actuator to re-direct the product, LEWCO recognized that the round products had differing heights and developed this system.

Modular plastic belting was chosen for the washer exit conveyor. This would allow for the minimal amount of moisture. Additionally, the round product could roll or slide sideways off the smooth top belt via a deflector arm.

Two different height fixed position deflector arms were installed over the belt. The lower profile part would pass under the first deflector arm and be diverted to the second lane. The taller product would be caught by the first deflector arm and sent down the first lane.

LEWCO’s patented Poly-V powered high density roller conveyors were used to complete the transfer of the product off the side of the Modular plastic belt conveyor. Those units in turn, fed the gravity roller conveyor where the product could accumulate.

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.