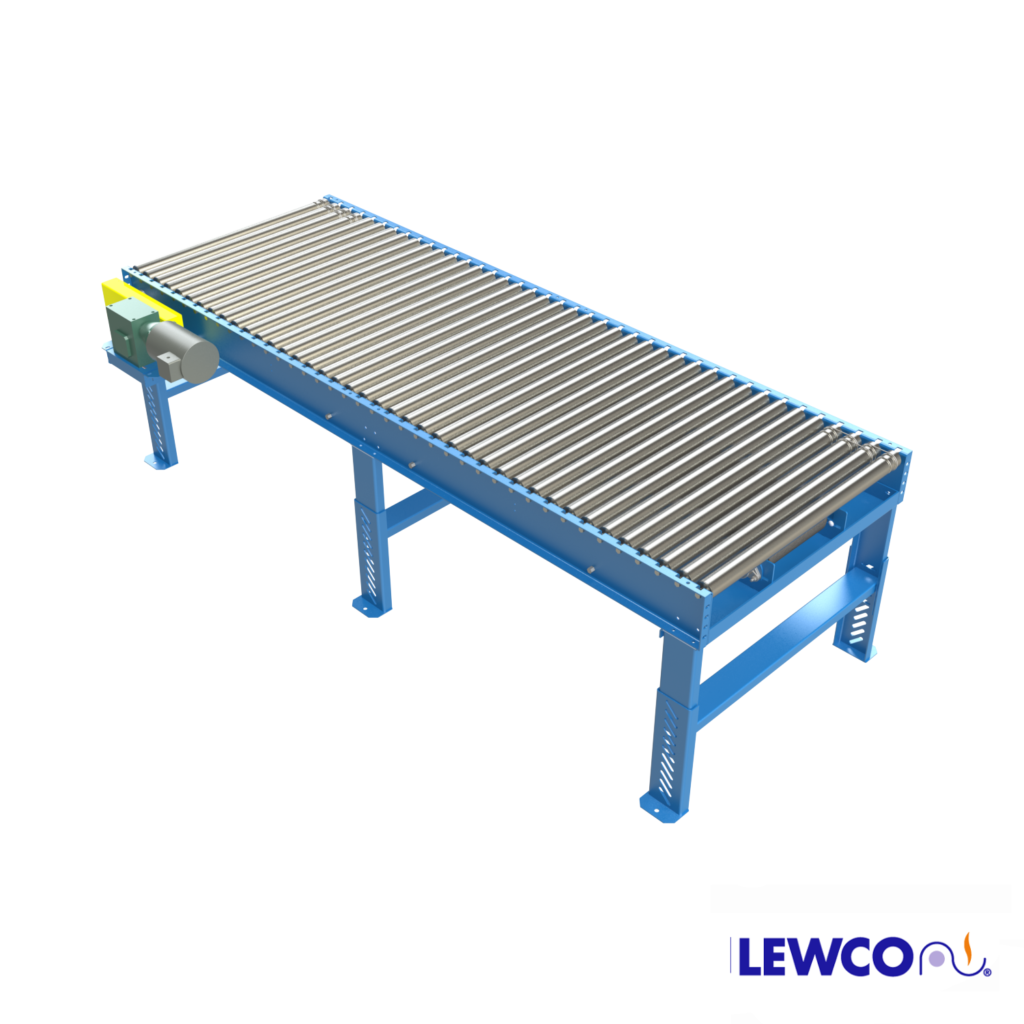

Model BDLR26 is a heavy duty, minimum pressure accumulation conveyor which provides an effective means of accumulating heavier products with minimal back pressure. This conveyor offers the same features of our BDLR25, with the added benefit of rugged, heavy wall rollers.

BETWEEN FRAMES: 15″ – 57″

LENGTH: 60″ – 960″

HEIGHT ELEVATION: 12″ to 108″

SPEED: Available in fixed speeds from 10 – 120 FPM

ROLLER CENTERS: 3″, 4.5″, 6″, 9″, 12″

ZONE LENGTH: 36″, 48″, 60″, 72″, 84″

ROLLERS: BDLR25 Roller – 2.50” diameter, 11ga wall tube. BDLR26 Roller – 2.625” diameter, 7ga wall tube. All rollers with 11/16” hex cold rolled steel axles, spring retained. Standard bearings are precision, grease packed bearings.

BELT: Standard 12” wide Trackmate PVC120 with clipper lacing supported on 1.9” diameter 16 gauge rollers with precision bearings. Optional non-woven NBR Ultimate.

DRIVE: Standard drive is an end drive, right hand side. Optional drives include end drive, left hand side; and center drive, right hand side.

MOTOR: 3/4 HP through 1-1/2 HP, Energy efficient and inverter duty motors also available. Voltages include 120/1/60, 230/3/60, 460/3/60, 575/3/60 & DC Voltage.

MINIMUM PRESSURE ACCUMULATION: Drive force is set by making adjustments to the pressure roller adjusting rods, typically located on 60″ centers.

ROLLER SURFACE: Standard roller surface is carbon steel. Optional surface for 2.5” rollers includes galvanized roller tube.

SUPPORT CENTERS: Standard supports are floor supports on 5’ nominal centers. Optional 10’ nominal centers.

CONVEYOR COLOR: Powder coated blue (RAL 5017). All guarding is yellow (RAL 1023) and moving parts are bright red orange (RAL 2008). Click HERE to see other standard color options. Custom colors also available.

As standard, controls are not included (provided by others).

Control Options:

- Variable Speed Controller

- Combination motor starter with disconnect, fixed speed

- Combination motor starter with disconnect, variable speed

- PLC (programmable logic controller) with HMI (human machine interface)

Optional:

- Photo eye sensor(s)

- Emergency Stop button(s)

- Emergency Stop Cable Pull Switch

- Motor Disconnect Switch mounted near motor, wired with SO cord.