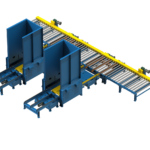

LEWCO Pallet Management and Robotic Interface

Recently a customer requested pallet handling conveyor for their (2) robotic palletizers. For flexibility and to maximize robot up-time, LEWCO built (2) pallet dispensers that could feed either of the two robots. To create a buffer queue for stacks of empty pallets, a chain conveyor was placed in front of each pallet dispenser. Floor space was tight, so LEWCO engineers worked closely with the customer to ensure the system fit within the available area.

LEWCO Engineering was able to reduce the footprint of our rear load Pallet De-stacker, and build the conveyors to feed it. The LEWCO Integrator supplied their own pallet locators, funnels, and stack squaring devices for the final installation.

Using LEWCO Professional Grade Pallet Handling Chain Conveyor, Pallet De-stackers, Chain Driven Live Roller conveyors, and Chain Transfers allowed the Integrator to focus on their core competency of Building and Programming the Robotic Palletizers.

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.