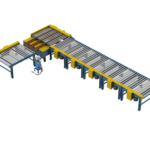

LEWCO Pallet Handling for Freezer Application

A customer came to LEWCO needing (2) systems to get pallets of frozen food in and out of a freezer without having to drive forklifts in and out. They only needed (1) dropoff/pickup zone per system in the ambient area, but multiple pallet zones inside the freezer. Pallets needed to turn 90 degrees once they passed through the freezer wall. LEWCO provided chain transfers for the 90 degree turns, using hydraulics instead of pneumatics due to the very low temperatures. In addition, all motors inside the freezer were prepped with motor heaters and other features to prevent damage in the cold. Forklift guards and backstops were designed to assist operators and help protect the equipment.

LEWCO provided full electrical controls and programming for this system, and performed shop set-up and testing of the systems for customer approval.

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.