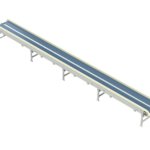

LEWCO Corrugated Sidewall Belt Conveyor

LEWCO recently provided an automotive tier-1 supplier with Slider Bed Belt Conveyors to convey automobile front valances and other body parts post paint from one workstation to the next workstation. The front valances could not sit directly on the slider bed so LEWCO designed a belt conveyor with corrugated sidewalls to keep the belt above the slider bed.

The customer also needed to convey smaller parts on the flat portion of the belt while still being able to sense parts present via a photo eye mounted in the slider bed looking up. This required LEWCO engineering to use (2) belts to leave the center open for the photo eye to look through. LEWCO worked with the end user to design the system to handle multiple configurations of front valances and other parts. The conveyors were set up and fully tested in our Sandusky, OH. plant prior to shipping to the customer’s plant.

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.