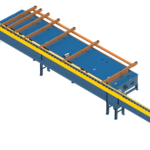

LEWCO Aluminum Extrusion Transfer Conveyor

LEWCO provided a powered roller and transfer system to interface with a punch system. This conveyor is handling aluminum extrusions of various lengths. Some components needed to be transferred to the punch, and others had to bypass it.

LEWCO built a multi-strand self-powered transfer with PowerTwist interlocking V-belts. roller conveyor is line shaft driven with non-marking orange polyurethane sleeves on the rollers, and UHMWPE covered guide rails and stops.

While moving the part to the saw the multi-strand transfer also served as a parts buffer, using indexing accumulation. The operator can choose to call for a part whenever they need a part, otherwise the parts index one at a time onto the transfer to feed the punch system.

After the punch process there is a duplicate transfer sending the completed part to another powered roller conveyor running adjacent to the bypass conveyor.

LEWCO designed and built the control system for this including set-up and testing at our plant prior to shipment. This reduced the time required for installation and commissioning.

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.