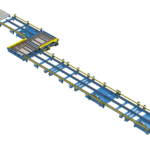

LEWCO Pallet Transfer Accumulation System

A brick manufacturer implemented multiple palletizing and accumulation systems that had to go around a building column and accumulate up to 4 pallets at the end of the line, on the other side of a wall.

The customer had a very finite window to fit all the equipment including some integration challenges. Utilizing modified standard MSCCH, Chain transfers, and CDLR conveyor, LEWCO Engineering was able to save on motors and provide effective equipment to accomplish this task.

The customer needed to accumulate up to (4) pallets at the end of the line. Utilizing several individual motors for the zones proved to be cost prohibitive. LEWCO Application Engineers developed the synchronous, reverse indexing accumulation model at the exit end. The initial pallet advanced far enough on accumulation conveyor to be free of the upstream conveyor – then the accumulation conveyor stopped. When a subsequent pallet was ready to be accumulated, the accumulation conveyor started and both the new and existing pallet advanced far enough for the second pallet to be free of the upstream conveyor – then the accumulation conveyor stopped. The same for the 3rd pallet. When the 4th pallet arrived at the end of the upstream conveyor it stopped, and the line was considered full. This alerted the lift truck driver to unload the conveyor.

Manual and automatic Interlock signals allowed the pallets to be safely unloaded. When the pallet and lift truck were clear of that end of the conveyor, the pallet indexing resumed – and the lane full indicator was turned off.

LEWCO’s Engineering team provided 2D and 3D models for the customer to approve and incorporate into their system layout drawings to ensure proper fit.

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.