“We are very satisfied with LEWCO’s performance, plan to continue to use you, and would give a high recommendation. Please pass on our thanks and congratulations to your entire team on a job well done!”

Jarrett Miller, Foresight Automation

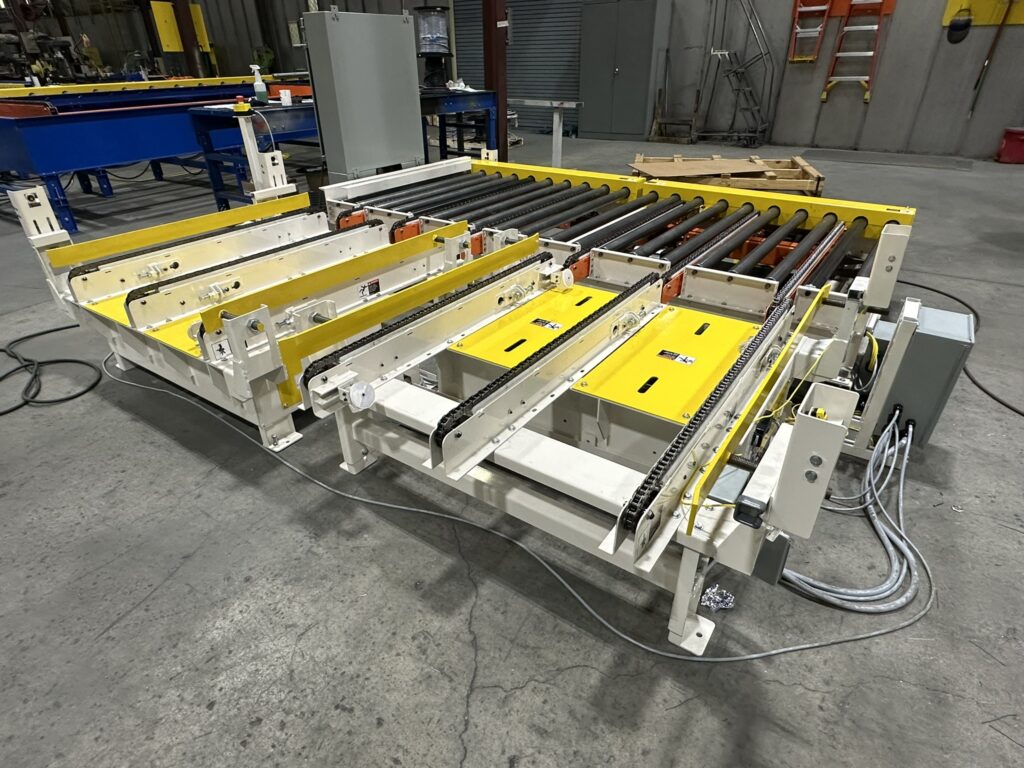

Order Summary: LEWCO provided a combination of CDLR, chain conveyors, pop-up chain transfers, and belt conveyors.

“Our customer really likes the conveyor they just received. The installation was easy & went perfectly. The 60” section for the dip tank went right into place without having to make any modifications. They were shocked on how well this project came together.”

Larry Anders, CFE Equipment Corp.

Lewco resolved persistent assembly line conveying problems with a custom Wheel Rail conveyor, replacing the inadequate equipment.

“My general impression of the equipment is excellent. Tech support was perfect. The couple of issues were small and to be expected. The only unexpected work was setting the parameters on the VFDs [which we figured out with the help of your electrical engineers].”

Ruell Reeves, Installer for Mezzanine Distributors

Order Summary

LEWCO provided powered round belt (PBR) conveyors, gravity conveyors, and belt driven live roller (BDLR) conveyors, as well as a complete control system.

“Whirlpool conveyor system buyoff went smoothly, and we’re completing installation this week. The Whirlpool team is impressed with the system’s appearance, and we’re looking forward to your electrical tech’s visit tomorrow to complete the startup.

Having spent 30 years in material handling, I’ve worked with LEWCO a bit throughout my career and have seen your impressive evolution. The improvements in your delivery reliability, and overall operations – particularly with Rob Wills and your current team – have been remarkable. LEWCO’s advancement to providing turnkey solutions aligns perfectly with ASI’s core strength – delivering and supporting comprehensive solutions for our customers.

This first year has given me valuable insight into your capabilities and product line. My growing confidence in LEWCO’s solutions means we can be more competitive in our pricing, which will benefit both our organizations. I see LEWCO becoming a cornerstone of our business in Tennessee. I’ve already told Rob that for any projects within three hours of Nashville, I’m happy to represent LEWCO’s interests if ASI can add value. LEWCO is the only conveyor solution that I will offer.”

Frank Eastman, Air Specialists, Inc.

Order Summary

LEWCO provided a CDLR Transfer Conveyor with inbound/ outbound Drag Chain Conveyors.

“I just received an order of 4 conveyors from you and completed the install last week. All are working fine and we are happy with the workmanship and quality. It was your order S000034128. I am ready to place an order that is almost a duplicate of that order.”

Buddy Terry, Barnett Millworks Inc.

Order Summary

LEWCO provided multiple various length belt conveyors (model MDCS) to complete their Belt Conveyor Assembly.

“Thank you again for working with us on this project. We had an opening ceremony for the logistics center today and the conveyors were a hit. The quality is exceptional. A few people I spoke with recognized your company and had great things to say. I’m happy we were able to get these systems installed in time, please extend our gratitude to the Lewco team for making it possible.”

Ben B., Axcelis Technologies

Order Summary

LEWCO provided (3) different Chain Driven Live Roller Conveyors (model CDDB25) each with their own PLC/ HMI control package. LEWCO Field Service Technicians also did complete installation.

“It was a pleasure working with the LEWCO team on our customer’s door panel conveyor project. They were able to complete the project earlier then committed to meet our customer requirements and kept us updated on the progress as it moved forward. They addressed any concerns that came up in a timely matter to supply the completed project. It would be a pleasure to work with their team on future projects.”

Jerry Roush, Persico USA.

Order Summary

1916 gravity conveyor with pneumatic pop-up stops and roller brakes, gravity transfer cars & track, conveyor fork truck barriers, and complete installation by LEWCO.

“I am beside myself with the workmanship and quality of your product. Thank you so much for following through on every aspect of my order from initial design stage to the on-time delivery. With the extreme supply chain issues affecting all corners of industry, LEWCO absolutely came through on my project.”

Jason Kalani Wong, IQ CORPORATION

Order Summary

LEWCO provided a range of Chain Driven Roller Live Conveyors, featuring models CDLR19, and CDRC19. In total there were 37 conveyors. Some conveyors were equipped with pneumatic pop-up stops. The conveyors were used to transport drums.

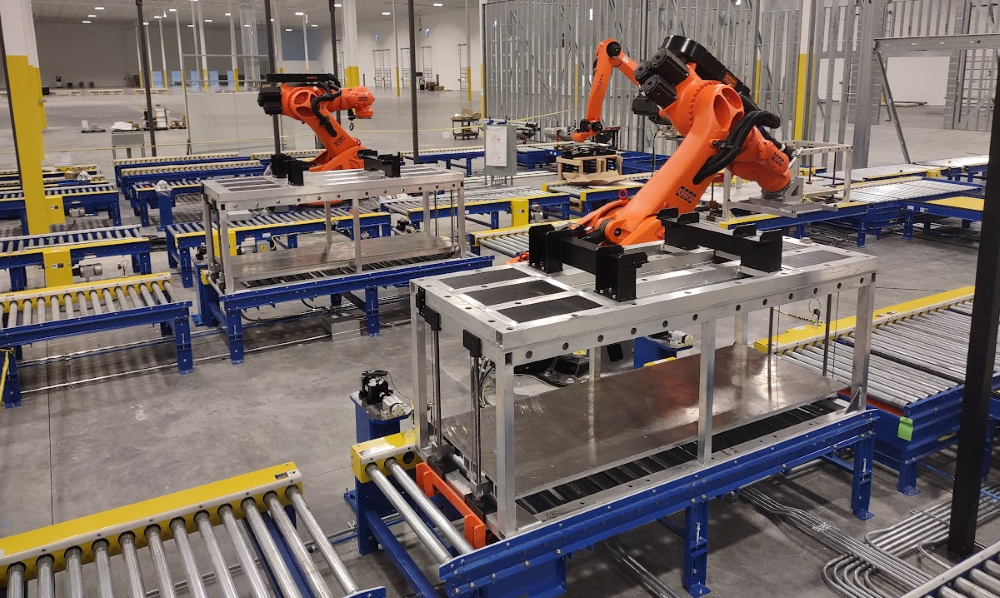

“We purchased LEWCO’s Multi-Strand Chain Conveyor and Gravity Conveyors for a full robotic cell we installed for our customer. LEWCO’s team was great to work with and their equipment was easy to integrate into our full assembly. All components arrived on time and as modeled. We look forward to continuing to work with them on our future projects!”

Elizabeth Braman, Altimate Controls

LEWCO provided multiple 3-strand drag chain conveyors for handling pallets, along with some 1916 gravity conveyor.

“I recently had my largest conveyor project, going to [a customer] in Michigan… long story short, I was quoted a 7-11 week lead-time… LEWCO was able to complete the full project is 6-7 weeks; [despite] some unforeseen delays on the end-users side. On this project, accurate quoting, an incredibly quick lead-time and customer support was imperative to Tiger’s success.

To my knowledge, lead times in the conveyor industry can be very volatile and be pushed back weeks with little to no heads up… this could not be further from my experience with LEWCO.

Pricing, thus far, has always seemed fair and allows salesman to put themselves in a position for success.

LEWCO’s knowledgeable and VERY helpful staff have went above and beyond the call of duty to assure a happy customer. On the project mentioned above, Ed Logan spent a considerable amount of time, even jumping on calls with the end-customer, to fully understand the project and quote accurately.

There are two LEWCO employees that I personally would like to thank for their professional expertise and customer service. Those being: Edward Logan and Steven Bechtel.

Ed Logan, not only quotes accurately and quickly. He also does a great job teaching me, so that I am better prepared for the next job. He has spent time with me and the customer, and is willing to go the extra mile. Steven Bechtel, on the same project, dropped everything to assist me and my crew while we were in the field installing. Steven was able to articulate instructions to my team, assuring our install and product was set up correctly.

Both of these men, in my eyes, are Tier 1 contacts and as a vender. I appreciate both of them and attribute them to my success on that project.

Everything stated above, is why LEWCO is my preferred conveyor manufacture and will be my first call on all conveyor needs”

Zach Zech, Tiger Material Handling