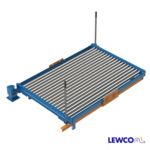

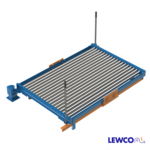

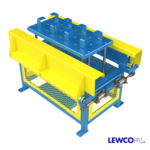

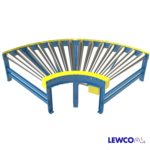

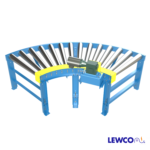

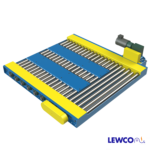

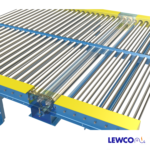

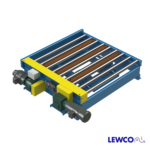

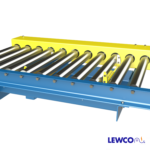

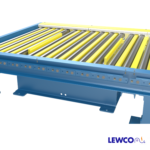

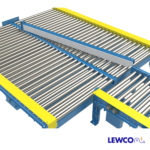

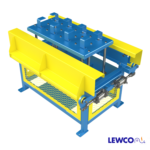

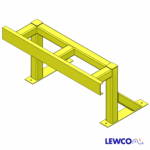

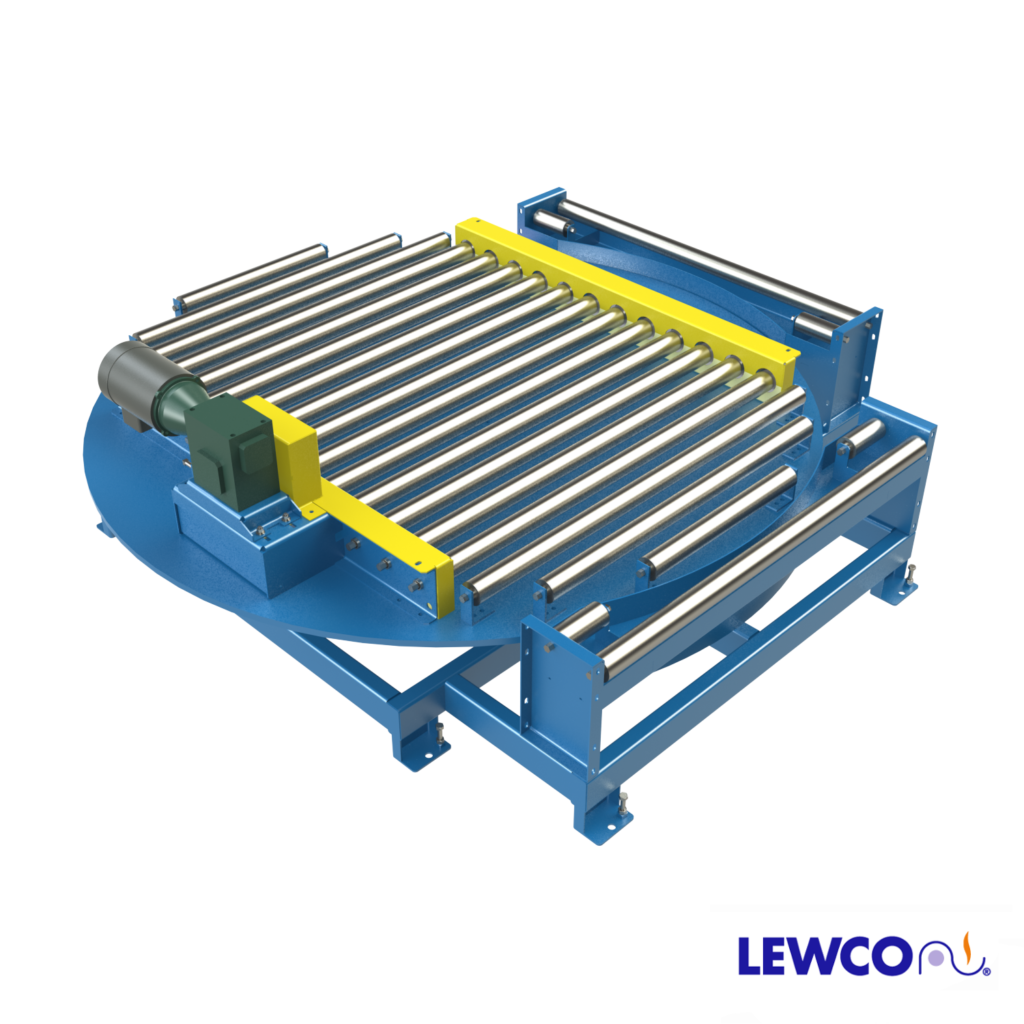

The Model PP90 Turntable features full 90° powered rotation. This unit is ideal for heavy duty applications requiring powered versus manual rotation. The PP90 can be fitted with various styles of powered conveyor such a multi-strand chain or chain driven live roller to convey material on and off of the turntable.

EFFECTIVE WIDTH: All rollers: 24″, 30″, 36″, 42″, 48″; for 2.5″ and 2.625″ diameter rollers: 51″, 54″, 60.

ELEVATION: 16″ – 48″

SPEED: 1.9″ diameter roller: 10 – 100FPM. 2.5″and 2.625″ diameter roller: 10 – 150 FPM

ROTATION: Standard 90 degree. Pneumatically driven. Hard stop.

ROLLER CENTERS: 4″ for 1.9″ diameter rollers. 4-1/2″ for 2.5″ and 2.625″ diameter rollers.

ROLLERS: 1.9” diameter rollers have 7/16″ hex cold rolled steel axles, spring retained. Either 12ga wall tube with precision grease packed bearings or 9ga wall tube with semi-precision grease packed bearings. 2.5″ diameter rollers, 11ga wall tube and 2.625″ diameter, 7ga wall tube are available with 11/16″ hex cold rolled steel axles, spring retained and precision grease packed bearings.

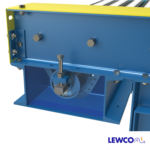

TURNTABLE PLATE: Standard is 3/8″ plate with slewing ring center bearing.

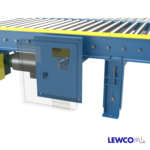

MOTOR: 1/2 HP through 2 HP. Energy efficient, inverter duty, and brake motors also available. Voltages include 115/1/60, 208/3/60, 230/3/60, 460/3/60 and 575/3/60 & DC Voltage.

AIR REQUIREMENTS: Requires 40PSI air pressure of clean, filtered air at consumption of approximately 0.05 cubic feet per 90 degree rotation.

FILTER REGULATOR: Supplied for main air supply at input, 3/8″ NPT port.

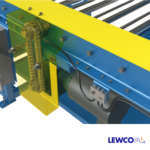

ELECTRICAL REQUIREMENTS: Includes home and 90 degree position proximity switches, 20 to 250 volt AC/DC, prewired and terminated in 6″ square junction box on outside of turntable frame. Photo-eye sensor available as option for product detection.

ROLLER SURFACE: Standard carbon steel. Optional orange polyurethane, 1/8″ wall for 1.9″ diameter, 12ga; 1.9″ diameter, 9ga; and 2.5″ diameter, 11ga. Optional galvanized for 1.9″ diameter, 12ga and 2.5″ diameter, 11ga.

TURNTABLE COLOR: OSHA safety blue powder (RAL 5017). All guarding is yellow (RAL 1023) and moving parts are bright red orange (RAL 2008). Optional colors available.