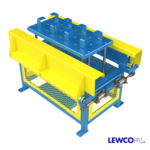

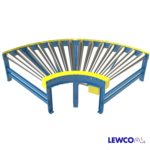

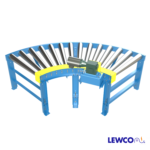

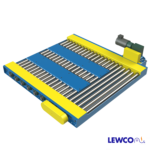

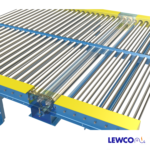

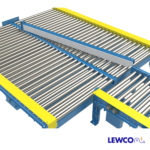

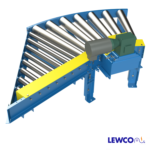

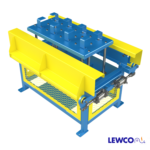

Model CDRC26 is a chain driven live roller curve conveyor commonly used with our CDLR26. It offers a positive drive for negotiating 90, 45, and 30 degree turns. The heavy wall rollers are is well suited for loaded pallets, drums, and containers in rugged industrial applications.

EFFECTIVE WIDTH: 12″ – 60″

DEGREES: 45°, 90°

BEGINNING ELEVATION: 7″ – 120″

ENDING ELEVATION: 7″ – 120″

SPEED: 10 – 120 FPM

ROLLERS: CDRC25 Roller – 2.50″ diameter, 11ga wall tube. CDRC26 Roller – 2.625″ diameter, 7ga wall tube. All rollers with 11/16″ hex cold rolled steel axles, spring retained. Standard bearings are precision, grease packed bearings.

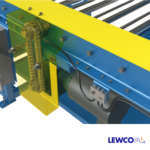

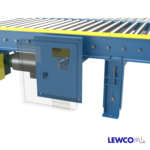

DRIVE: Standard drive is mounted high near center of conveyor length on chainbox side. Optional drives include drive mounted low or drive mounted below and within, near center.

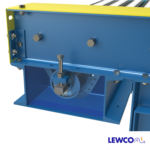

FRAME: Standard frame includes 6” channel on chain box side and 4” channel on opposite side with roller set high in frame. Optional frame options include 6”channel on opposite side with roller set low in the frame, or structural 6@8.2# & 4@5.4# with rollers set high, or structural 6@8.2# both sides with roller set low.

MOTOR: 1/2 HP through 2 HP. Energy efficient and inverter duty motors also available. Voltages include 120/1/60, 230/3/60, 460/3/60 and 575/3/60 & DC Voltage.

ROLLER COVERS: Standard roller surface is carbon steel. Optional roller covers for 2.5″ rollers includes galvanized roller tube, polyurethane roller sleeves, Ultrex accumulation sleeves.

SUPPORT CENTERS: Standard supports are floor supports on 5’ center.

CONVEYOR COLOR: OSHA safety blue powder (RAL 5017). All guarding is yellow (RAL 1023) and moving parts are bright red orange (RAL 2008). Optional colors available.