BETWEEN FRAMES: 9″ – 39″

HEIGHT ELEVATION: 6.75″ to 48″, Consult factory for incline/decline applications

LENGTH: 6″ – 1200″ see note below in DRIVE

ROLLER: 2-1/2″ diameter tapered to 1-11/16″ diameter, 14 gage galvanized steel with precision grease packed bearings, 7/16″ hex spring retained axles.

ROLLER CENTERS: Nominal 3″

CONVEYOR SPEED: Available in fixed speeds from 20 – 250 FPM

DEGREES: 30°, 45°, 90°, 180°

DRIVE BELT: Standard belt is 83A durometer.

DRIVE: 24 volt DC motor with drive spool capable of driving up to (16) rollers maximum. Conveyors of longer lengths require multiple drive motors. Standard power supply is 40 amps and is capable of supplying power to up to 40 motors.

CONTROLS: Zero pressure accumulation cards and zone sensor photo eyes included as standard.

ROLLER COVERS: Standard roller is galvanized steel. Optional polyurethane sleeves available.

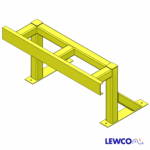

FRAME: Conveyor frame is 6.50″ high, 12 gage steel channel with bolted cross members.

SUPPORT CENTERS: Standard supports are floor supports on 10’ nominal centers. Optional supports on 5’ nominal centers. Ceiling supports are also available.

CONVEYOR COLOR: Powder coated blue (RAL 5017). All guarding is yellow (RAL 1023) and moving parts are bright red orange (RAL 2008). Click HERE to see other standard color options. Custom colors also available.