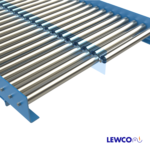

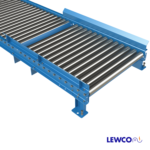

1.9″ Diameter 16 ga. Gravity Roller Spurs are used to divert off, or merge on, main trunk line conveyors at various angles. They are often used when several lines transfer onto a main conveyor line, from work stations or similar applications. Spur sections can easily incorporate Straights and Curves.

ORIENTATION: Left or Right

BETWEEN FRAMES: 13″ – 51″ (See chart below)

LENGTH: 28″ – 106″ (See chart below)

ROLLER CENTERS: 3″, 4.5″, 6″

DEGREE: 30° , 45° (See chart below)

ROLLERS: 1.9″ dia., 16ga wall tubes with 7/16″ hex cold rolled steel axles, spring retained. Standard bearings are light oil lubricated. Optional bearings include combinations of precision, semi-precision, and non-precision construction with light oil or grease packed lubrication.

ROLLER TUBE & COVER OPTIONS: Optional Orange Polyurethane, 1/8″ wall or galvanized tube.

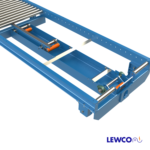

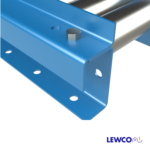

FRAME CONSTRUCTION: Standard F97 set high 3-1/2″ x 1″ x 12ga formed steel channel with bolted 2″ x 8ga galvanized angle crossties. Optional F38 set low 4-1/2″ x 1-1/2″ x 12ga.

FRAME CONNECTION / COUPLINGS: Bolted butt couplers on both ends of channel.

CONVEYOR COLOR: Powder coated blue (RAL 5017). Click HERE to see other standard color options. Custom colors also available.

| 1916S COMBINATIONS | ||||||||

|---|---|---|---|---|---|---|---|---|

| BF | LG | DEG | BF | LG | DEG | BF | LG | DEG |

| 13 | 40 | 30 | 23 | 57 | 30 | 37 | 81 | 30 |

| 13 | 28 | 45 | 23 | 38 | 45 | 37 | 52 | 45 |

| 15 | 43 | 30 | 25 | 61 | 30 | 39 | 85 | 30 |

| 15 | 30 | 45 | 25 | 40 | 45 | 39 | 54 | 45 |

| 17 | 47 | 30 | 27 | 64 | 30 | 43 | 88 | 30 |

| 17 | 32 | 45 | 27 | 42 | 45 | 43 | 58 | 45 |

| 19 | 50 | 30 | 31 | 71 | 30 | 47 | 99 | 30 |

| 19 | 34 | 45 | 31 | 46 | 45 | 47 | 62 | 45 |

| 21 | 54 | 30 | 33 | 74 | 30 | 51 | 106 | 30 |

| 21 | 36 | 45 | 33 | 48 | 45 | 51 | 66 | 45 |

Options & Accessories:

- End Stops

- Guardrail

- Mechanical Roller Brakes / Speed Control

- Pneumatic Pop-Up Stops & Roller Brakes

- Walkover Plates

- Drip Pans

- Bottom Covers

- Fork Truck Barriers

Floor Supports:

- Floor supports are not included unless specified. Supports can be added to achieve a variety of heights (Top of Roller).

- Supports can be added with different beginning and ending elevations to achieve gravity flow.

- Floor supports can be provided on 5′ or 10′ nominal centers. It is recommended that conveyors wider than 32″ have supports on 5′ centers. It is also recommended that conveyors with height elevations above 35″ use knee braces (model KB17 or KB18).

- View all support options

| Weight Capacities | ||||

|---|---|---|---|---|

| Model | Roller Capacity | Gravity Conveyor Capacity | ||

| No Supports (set on floor) | Supports on 5′ Centers | Supports on 10′ Centers | ||

| 1418 | 50# | 1,000# | 900# | 350# |

| 1916 | 250# | 3,300# | 3,200# | 1,300# |

| 1912 | 260# | 3,300# | 3,200# | 1,300# |

| 1909 | 300# | 3,300# | 3,200# | 1,300# |

| 2514 | 290# | 3,300# | 3,200# | 1,300# |

| 2511 | 750# | 8,100# | 8,000# | 3,750# |

| 2607 | 750# | 8,100# | 8,000# | 3,750# |

| 3530 | 2,000# | 22,100# | 22,000# | 11,000# |

Note: Capacities listed are an estimate only to be used as a general guideline.

Capacities are based on evenly distributed loads. There are several variables that factor into determining capacity, including how the product is loaded.

When a conveyor is on floor supports, the conveyor frame rails are typically the limiting factor when determining weight capacity. In other words, if a conveyor frame is set directly on the floor, it can handle much more weight than a conveyor on supports.

If you’re unsure about selecting the right conveyor, please consult our sales team and we’d be happy to help you!