LEWCO Ergonomic Container Handling & AGV Interface

An automotive supplier had a very tight space to manage the movement and storage of the product racks. The existing AGV’s dropped off and picked up the racks. The customer needed some product buffer on both the infeed and exit portions of the line. Additionally, the operator interface required that the racks be oriented for ease of operator access to the parts inside the rack.

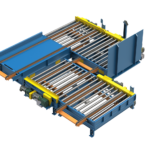

Since the rack weight is less than 1,300# (full), LEWCO was able to provide PLV-25 powered roller conveyor along with integral pop-up chain transfers at the elevation to integrate with the AGV. The operator station included a lift and tilt mechanism under the reversing powered roller conveyor.

LEWCO provided all the controls (including the touch screen machine interface) and ran a complete system run-off at our facility. The customer approved the run-off, and is proceeding with more identical systems.

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.