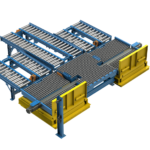

LEWCO Ball Tables with Pneumatic Pusher

An automotive parts supplier needed an ergonomic solution to provide a production parts buffer for both full and empty containers and the operator workstations.

To build a complete system the LEWCO integrator provided the lift and tilt stations. LEWCO built the ball transfers, mounted them to the lift tables and roller conveyor. At the onset, the plan was to manually push the empty container to the center take-away line. The customer then determined that full containers may need to be pushed out of the way from time to time, too. LEWCO Engineering developed an integral, low profile pusher to accomplish this task, with minimal impact on the overall height.

LEWCO also designed mechanical safety devices to eliminate inadvertent product movement. Lifts and tilts had to be the correct position in order for product to advance. Similar devices prevented back travel, or forward travel in unsafe conditions.

The customer wisely elected the option to fully set-up and run-off this conveyor at our facility. After some minor adjustments, the test was successful. This allowed the customer to install this system in a very short time window – minimizing its impact on the production line.

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.