Gentle Handling of Aluminum Product on LEWCO Conveyor

A manufacturer of high-end aluminum door panels recently contacted LEWCO to supply a challenging lift transfer. The new equipment needed to be integrated with existing equipment and allow for future expansion. Care and protection of the finished aluminum part surface was a requirement.

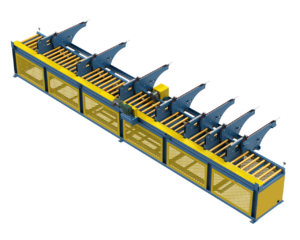

In this process aluminum extrusions are received from cutting equipment at 90-120 FPM, then raised and transferred sideways onto a multi-belt accumulation conveyor, and indexed off as needed for production. The extended lift is needed to cross over existing in-plant process equipment.

LEWCO supplied full controls for this project, including PLC programming, and tested the conveyors in-house with customer-supplied product.

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.