CDLR: Right-Angle? Right Solution!

New customer to LEWCO (paraphrased):

“We need to convey 40″ x 48″ plastic pallets in a washdown environment. The load can be up to 4ft. tall and is slightly unstable. The maximum weight is 600 lbs. The tricky part is the pallets are being fed slowly from a 4.5” elevation chain conveyor, and I need the new conveyor system to take the pallet at that low-elevation then turn or divert 90-degrees. I do not want to raise the pallets or dig a pit in the floor. The rate is 30 pallets per hour. I need buffer zones for 10-pallets as well. Pallets will be picked up by an Autonomous Mobile Robot (A.M.R.). I can send you the 27-page spec. Can you help?”

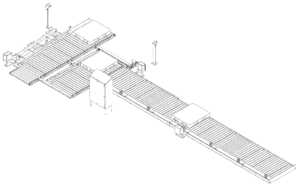

LEWCO response: “No problem, this is right up our alley.” The Solution? Chain Driven Live Roller (CDLR) conveyor with a custom pusher arm for 90-degree transfer.

Conveyor System Features:

- Washdown-rated 24VDC motorized drive rollers (M.D.R.) from Itoh-Denki with smart Ethernet/IP, 2-zone control cards.

- Stainless steel rollers with ProCoat® Roller Chain. ProCoat® chain offers the corrosion resistance of stainless steel, while maintaining the strength of carbon steel, at a fraction of the cost of traditional stainless.

- Adjustable guide rails.

- Walkover plates between rollers.

- Photo Eyes for zero pressure accumulation.

- Ultrasonic sensors to stop the conveyors when the A.M.R or a fork truck are present for load/ unload.

- Control package designed and built in-house by LEWCO.

Prior to shipping, the complete system was fully assembled and wired so that the customer could see their equipment in action during testing. The F.A.T. was a success. Product shipped on-time and LEWCO was fortunate to earn another happy customer.

Fill out our Chain Drive Live Roller RFQ form today and get your custom LEWCO CDLR quote!