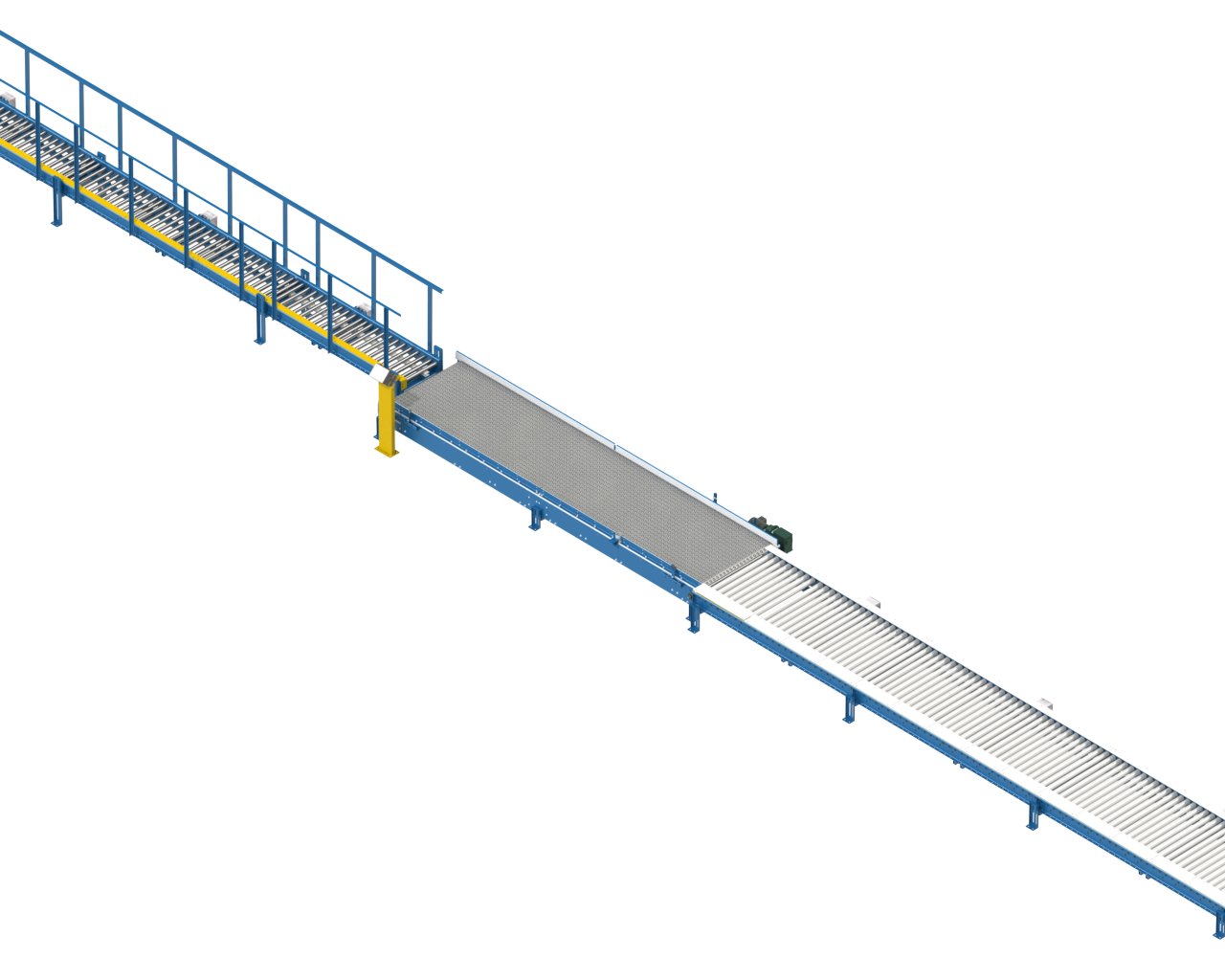

LEWCO Poly-V Driven Conveyor with Bump Turn

Recently LEWCO developed, tested, and delivered a process conveyor for a major appliance manufacturer. This conveyor was built to handle custom pallets holding multiple parts needed for final assembly. The rectangular pallet bottom needed to be introduced with narrow side leading, but delivered with wide side leading at the end of the line. This was accomplished with a bump turn unit near the center of the line to rotate the pallet 90 degrees.

Pallets accumulate in zero pressure fashion, in both pallet orientations. 24vdc motorized zones provide an economical means to drive the pallets individually. This allows the conveyor to act as a buffer between process steps that have variable time durations.

LEWCO controls engineers worked with the customer and end user to design a user-friendly “turn-key” controls scheme, which was fully built, wired and tested in house at LEWCO.

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.