Pallet Stacker & Dispenser for Variable Size Pallets

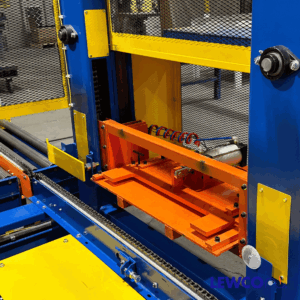

Faced with a significant space constraint, our customer needed a material handling solution capable of moving three fully loaded pallets per minute. Enter LEWCO. In our latest video, we showcase two key components of this high-performance system: our high-lift pallet transfer and variable-size pallet stacker. While these are the stars of the footage, they’re just part of a broader, finely engineered solution operating behind the scenes.

The system integrates seamlessly with existing conveyors on both ends of the powered roller section, as well as a central conveyor workstation where a team member inspects each load. When a full pallet arrives at the powered rollers, the rollers stop, the chain transfer lifts, and the pallet is smoothly delivered to the inspection station.

From there, products are either removed for processing or directed to a repair line positioned to the left of the rollers. Once a pallet is emptied, it is advanced to the chain transfer. A photo-eye sensor detects its presence, triggering the pallet transfer to lift and feed the empty pallet into the stacker.

At the heart of the system is a custom-engineered LEWCO control panel, equipped with a user-friendly touch screen HMI. With pre-programmed automatic modes, operators can easily select product destinations and keep workflows moving at peak efficiency.