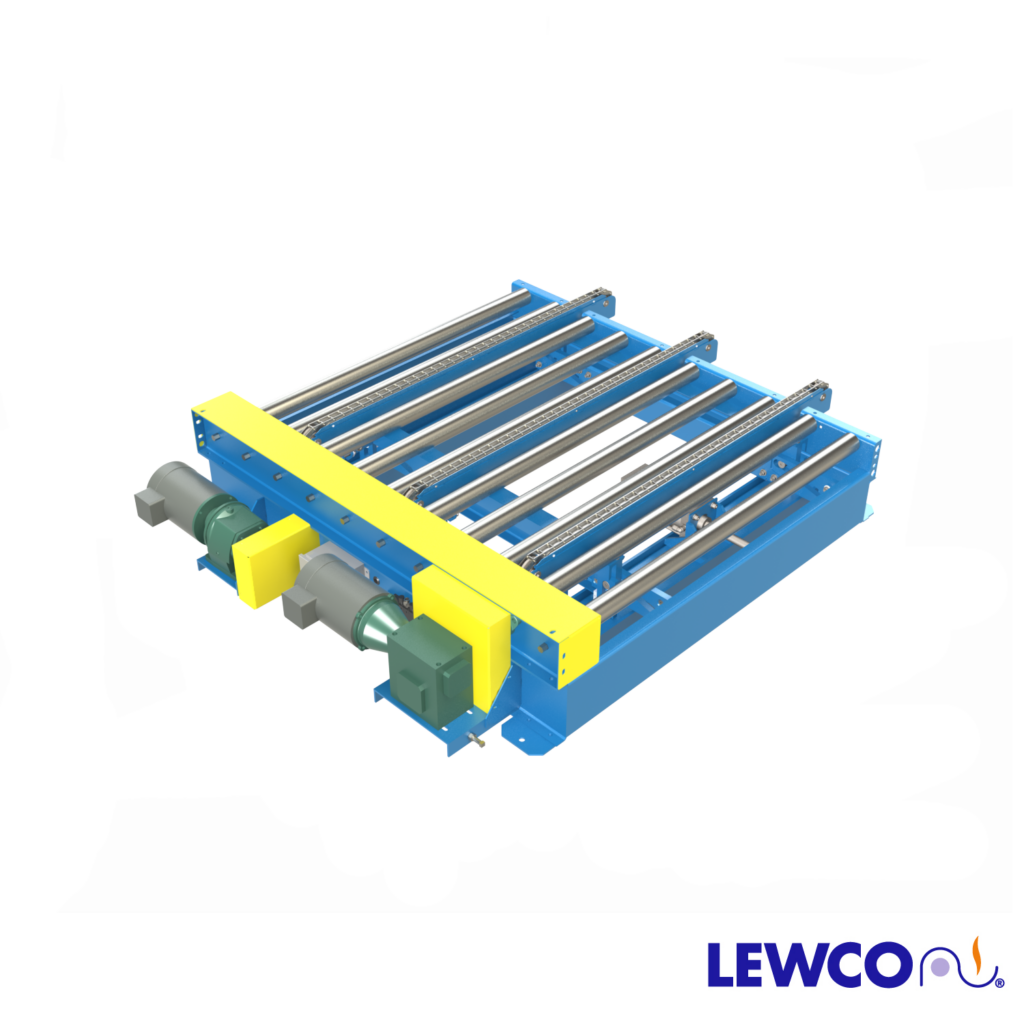

Chain Transfer Conveyors provide a method for right angle,

directional changes within a Chain Driven Live Roller Conveyor

(CDLR). Product conveys on the roller conveyor and when

prompted, a pneumatic cylinder raises the chain up between the

rollers and transfers product off the conveyor. This rugged

design, capable of handling up to 1,500 lbs., is ideal for

transferring pallets, containers, structural steel, and similar heavy

loads. The “external” chain design is useful for transferring

products that require minimal gaps in order to convey properly.

CHAIN CENTERS: 15″ to 48″

NUMBER of STRANDS: 2, 3, or 4

EFFECTIVE WIDTH: 36″ to 60″

ROLLER CENTERS: 4.5″ or 6″

ROLLERS: 2.50″ dia. x 11ga. mild steel tube with 11/16″ hex axle, spring retained, with precision, greased packed ABEC bearings, and #60 sprockets. Standard roller surface is carbon steel. Roller options include: cotter pin retained axle, galvanized roller tube, polyurethane roller sleeves, and Ultrex accumulation sleeves.

CONVEYOR CHAIN: Standard C60 chain guided by UHMW track. Optional steel track.

POSITION DETECTION: (2) Proximity sensors to detect raised/ lowered position, pre-wired to junction box.

AIR REQUIREMENTS: Transfer lift is pneumatically actuated. Requires 60 PSI pressure. Approximately 0.19 cubic feet per lift cycle. Includes Filter-Regulator-Lubricator and 2-position double solenoid operated air valve, 120-volt or 24-volt DC coils. Devices come plumbed and pre-wired to a junction box.

MOTOR: 3/4 HP totally enclosed fan cooled inverter-duty motor. Optional power off brake motor or non-inverter-duty motor. Standard voltage is 230/460V/ 3Ph/ 60Hz. Optional voltages include: 115V/1Ph /60Hz, 208V/1Ph/ 60Hz, 230V/ 1Ph/ 60Hz and 575V/ 3Ph/ 60Hz. 24VDC Motorized driven roller (MDR) also available.

SPEED: Available in fixed speeds from 10 – 50 FPM (feet per minute). Reverse capability optional.

CONVEYOR COLOR: Powder coated blue (RAL 5017). All guarding is yellow (RAL 1023) and moving parts are bright red orange (RAL 2008). Click HERE to see other standard color options. Custom colors also available.

As standard, controls are not included (provided by others).

Control Options:

- Variable Speed Controller

- Combination motor starter with disconnect, fixed speed

- Combination motor starter with disconnect, variable speed

- PLC (programmable logic controller) with HMI (human machine interface)

Optional:

- Photo eye sensor(s)

- Emergency Stop button(s)

- Emergency Stop Cable Pull Switch

- Motor Disconnect Switch mounted near motor, wired with SO cord.

Supports:

- No floor supports

- 5″ formed channel jack bolt supports, adjustable 1″ to 2″ (model SPJ5)

- Supports can be provided with optional adjustable top plate for conveyors on an incline or decline

- Floor supports can be provided on 5′ or 10′ nominal centers. It is recommended that conveyors wider than 32″ have supports on 5′ centers. It is also recommended that conveyors with height elevations above 35″ use knee braces (model KB18)

Guardrail:

- Bolts on one side of the conveyor frame

- See drawing for further details