Used to stop non-powered/ gravity rollers from spinning. A pneumatically activated steel channel with a high friction top surface presses against the bottom of a series of non-powered conveyor rollers to prevent them from turning. When air pressure (60PSI or more) is sent to the brake, the brake releases from the rollers. Removing that air pressure allows the spring to return the brake channel against the bottom of the rollers. Brake will still stay engaged in the event of air pressure loss. Available in 2’, 3’, & 4’ lengths for 1.9” and 2.5” diameter non-powered roller conveyors.

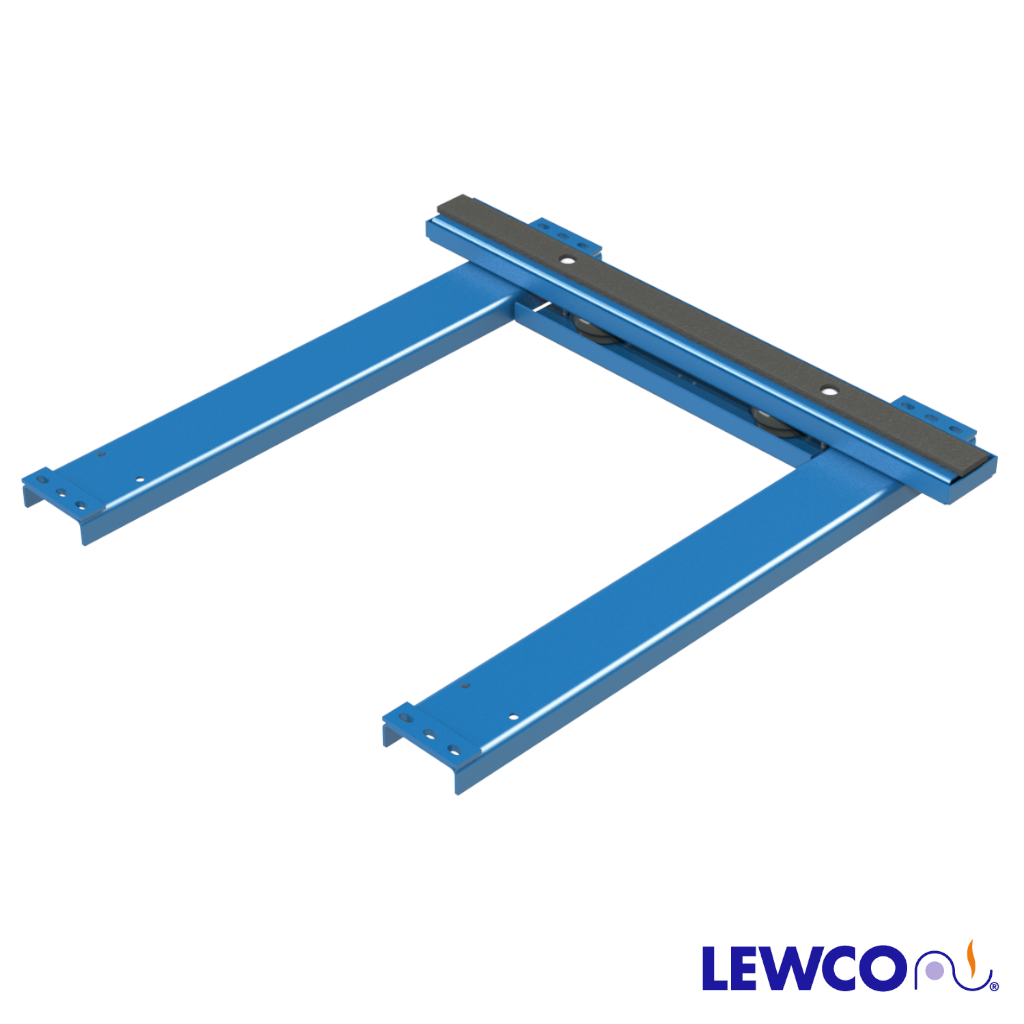

OVERALL WIDTH: 10″ – 66″

FRAME DEPTH: 3.5″, 4″

LENGTH: 24″, 36″, 48″

ROLLERS: Standard assembly is mounted to 1.9″ diameter roller conveyor. Optional configuration mounts to 2.5″ diameter roller conveyor with shim pack.

MOUNTING: Escapement frame bolts on to the bottom flange of conveyor frame.

OPERATION: Inflating the air bag disengages the escapement stop.

AIR SPRING: (2) 3-1/2″ dia. air springs, plumbed with 1/4″ nylon tubing to tee fitting.

AIR REQUIREMENTS: Standard requires 30-40psi of clean, filtered, regulated air at consumption of approximately 0.005 cubic feet per cycle. Optional valve and filter/regulator/lubricator available. NOTE: Pressure loss can occur over extended periods with no use.

COLOR: Bright red orange (RAL 2008) per OSHA safety standards for moving parts.