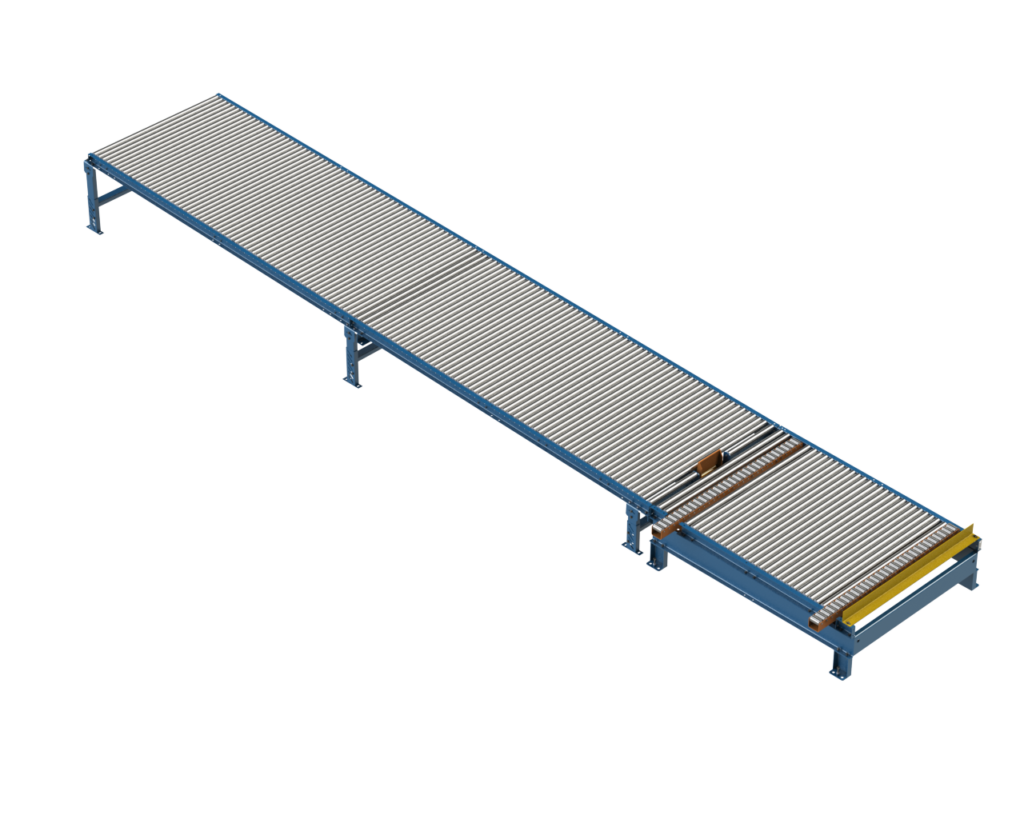

LEWCO Gravity Flow for Totes

A customer approached LEWCO in need of a 40ft long gravity flow conveyor for plastic shipping totes that included a right-angle transfer at the end.

Gravity flow conveyor has inherent risks that sometimes a product might not move automatically. The same product and load may successfully convey 9 times in a row and on the 10th time gets stuck and may need assistance to continue moving. Often, the next product contacting it is enough to get it moving again. This risk was understood by the customer.

All gravity conveyor capacities are based upon a stable, uniformly distributed load. Off-center, uneven, or unstable products affect the ability of gravity flow conveyor to operate. The condition of the contact surface is also a significant factor in success. To reduce this risk, a test lane set-up with the actual conveyor being considered and customer product is strongly recommended. LEWCO can perform this test on a Time & Material basis.

The size and weight of the product to be handled in this application was very consistent but the concerns noted above were understood by the customer.

LEWCO devised a plan to solve several concerns:

• The exit end transfer rails are level to the floor despite the infeed conveyor being at a decline.

• Modified conveyor design to allow for frame mounted speed controls to be re-located in the field with hand tools.

• High density roller centers for smoother product conveying.

• Use of LEWCO’s single cylinder pallet escapement stop device to assure one product releasing into the transfer at a time.

• Set-up and test the actual product on the conveyor prior to shipment. This was very key to success.

With our experienced Engineering estimates, the testing was completed quickly and within quoted budget. This test also saved the customer installation time – allowing for the conveyor to be completely installed on one weekend.

LEWCO offers a quality product that is cost effective and built to the highest industry standards. Reduction in manual material handling, improved product flow, better ergonomics and elimination of shipping damage are just some of the benefits of a well-designed LEWCO conveyor system.

LEWCO has an extensive amount of experience designing and manufacturing Conveyor Equipment. Our highly knowledgeable staff of Application Engineers can help assess your application and recommend cost effective solutions. You can email your requirements to conveyorsales@lewcoinc.com, call (419) 625-4014 ext.4003, or request a quote on our website.